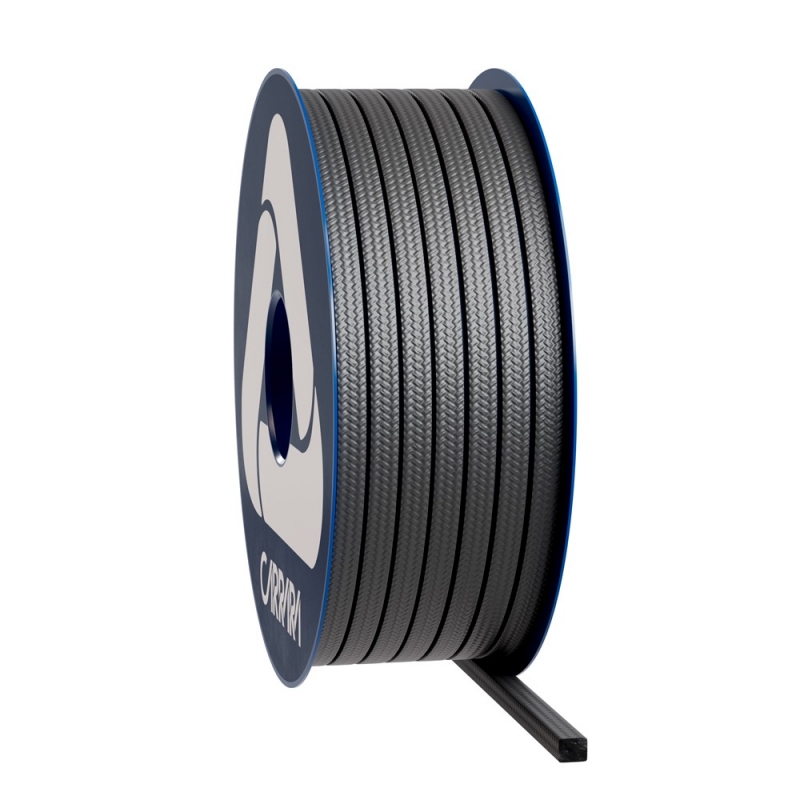

Composition

ePTFE yarns with encapsulated graphite and silicone lubricant.

Characteristics

The compression packing for dynamic services style GL7000 is made with pure egPTFE yarns filled with graphite. The encapsulation of the graphite in the expanded PTFE reduces the its migration and mitigates the thermal expansion of the sealing, common to all PTFE packing.

Applications

The egPTFE packing style GL7000 is recommended for all dynamic industrial applications. It is an excellent general purpose sealing suitable for all fluids with the exception of the strong oxidizers and those not compatible with the PTFE and the graphite. Its high elasticity and flexibility allow it to adapt perfectly to flanges and irregular surfaces, ensuring a secure and long-lasting seal. The compression packing style GL7000 is flexible, elastic, easy to cut and install. It is a universal braided packing egPTFE for pumps, agitators and mixers that provides reliable service and moderate shaft wear.