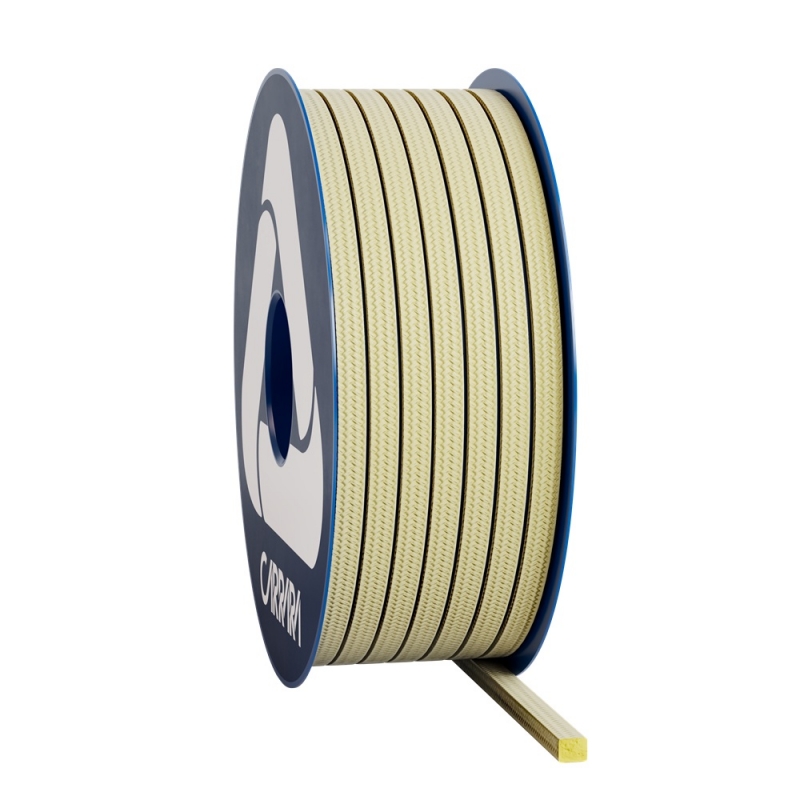

Composition

- Continuous aramid yarns

- PTFE impregnation

- Lubricant silicon free

Characteristics

The continuous thermostable aramid fiber ensures high mechanical strength and thermal stability, allowing the packing to effectively perform its function even in the presence of aggressive and abrasive fluids. The presence of PTFE dispersion and the inert silicone-free lubricant also ensures constant lubrication and reduces friction between the packing and the pump shaft, improving performance and product life.

Applications

The K6600C aramid packing is the ideal choice for centrifugal and piston pump applications with abrasive fluids. Thanks to its wear resistance properties, this packing is able to provide reliable and durable sealing in difficult conditions. K6600C is the perfect solution for applications that require high resistance to wear. It is recommended to protect the shaft’s wear area during operation with K6600C.