Composition

- Aramid yarns

- ePTFE yarns with encapsulated graphite and silicone lubricant

Characteristics

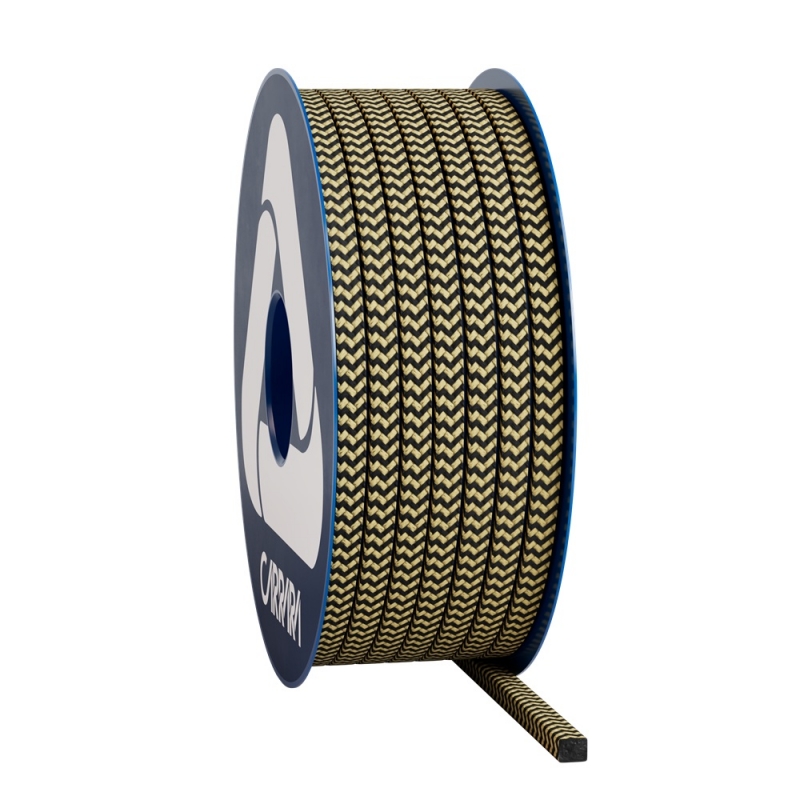

The style GL7676 is a special packing produced with an innovative braiding technique. It is made with egPTFE and aramid yarns combined in the "zebra" mode. This configuration improves the packing's resistance to the extrusion and it is able to reduce the wear of the sealing.

Applications

GL7676 is the packing for dynamic applications for all services with industrial fluids compatible with graphite, PTFE, and aramid fiber. The GL7676 packing is made with two yarns braided in a "zebra" pattern to create a braid whose properties are intended to combine the main characteristics of both: the toughness of aramid and the versatility of egPTFE. The GL7676 packing has shown particular suitability for use in pumps intended for slurry, for pumping water for industrial use in filtration and demineralization cycles.