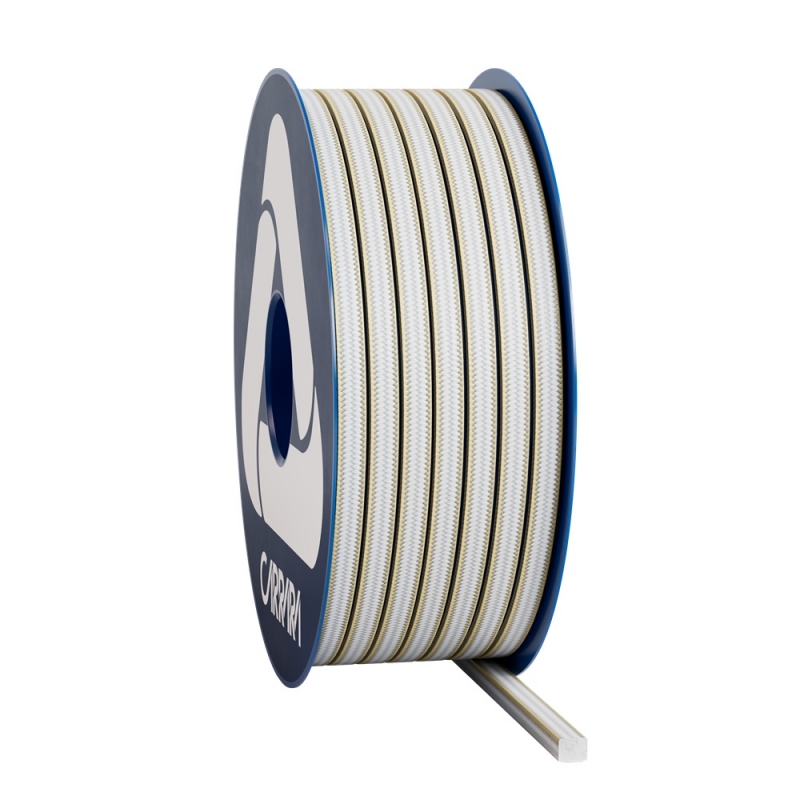

Composition

- Pure PTFE yarns

- Aramid yarns

Characteristics

PT5600K is a packing braided with PTFE yarns in the core and Aramid yarn on the corners to improve the resistance. PT5600K is a packing suitable for reciprocating and centrifugal pumps, mixers and valves, with acids, solvents, abrasive substances in paper mills, in the food and chemicals industries.

Applications

The packing PT5600K is braided with pure PTFE yarns and with aramidic yarns on the corners, in order to improve the mechanical resistance in high pressure or dry services. The PTFE and aramid fiber PT5600K can be used with all compatible acidic and basic fluids, both for sealing valve stems or static seals in general, and for sealing reciprocating pumps and low-speed agitators. Available in the striped version PT5656, the PT5600K braid guarantees high performance and is suitable for a wide range of static applications where fluid sealing is required in the presence of high pressures.