Clamp Connectors Ω-Lock

The market for mechanical joints of the Clamp Connector type is based on well-established standards that ensure full interchangeability.

Clamp Connectors Ω-Lock were developed on this principle: a new product line designed to offer freedom of choice, maximum compatibility, and reliable performance in the most demanding applications.

Clamp Connector Ω-Lock is designed to integrate seamlessly into new or existing systems without modifications, reducing procurement lead times, simplifying installation activities, and optimizing costs throughout the entire plant lifecycle. Dimensional and functional interchangeability allows immediate use, with no dependency on specific suppliers.

Designed to operate at the design pressures defined by piping classes, Clamp Connectors Ω-Lock ensure high performance even in the presence of external loads, such as bending moments and axial forces, typical of complex industrial plants.

Clamp Connectors Ω-Lock represent a modern, flexible, and competitive solution:

a strategic choice for those seeking technical reliability, true interchangeability, and commercial advantage, today and in the future.

The Clamp Hub Connector Ω-Lock is a high-integrity connection system designed to provide a more compact, lighter, and more robust alternative to traditional bolted flanges. It is an essential component in the process industry, used in high-pressure and high-temperature applications within the Oil & Gas, Power Generation, and Petrochemical sectors.

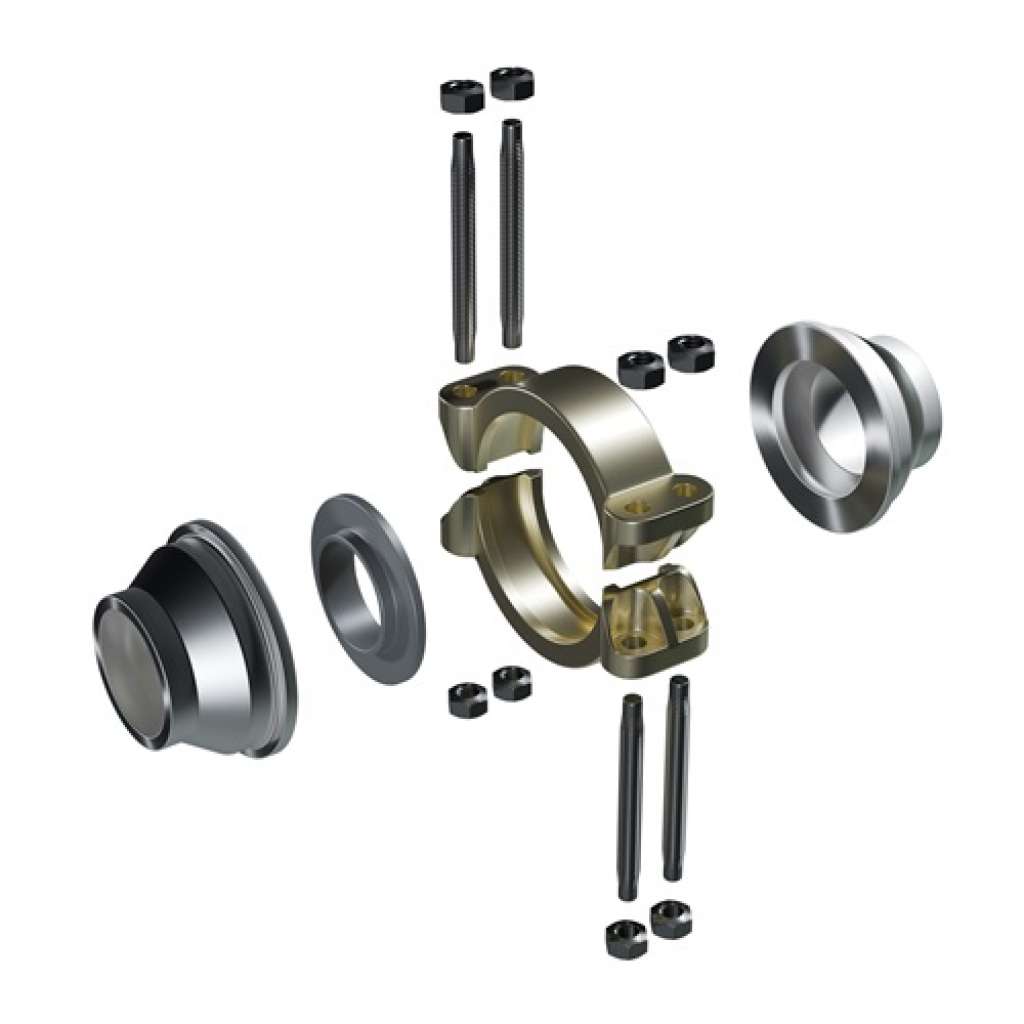

The system consists of four main components:

Hub: End components welded to the piping or equipment. They feature a conical (or spherical) internal profile, which is essential for the positioning and energization of the seal ring. Available configurations include buttweld hubs and blind hubs.

Seal Ring: A metallic element providing a metal-to-metal seal. It is a self-energized component, designed so that increasing internal pressure enhances the sealing action.

Clamp: Typically composed of two segmented halves that enclose and draw the hubs together. Its geometry converts the bolting tightening force into an axial preload on the hubs, thereby energizing the seal ring.

Bolting: Used to assemble and tighten the clamp halves.

Connectors are specified according to pressure classes and pipe sizes as defined by the project specifications.

Design and Technical Requirements

The design of Clamp Hub Connectors Ω-Lock is governed by stringent international codes and standards to ensure structural integrity under critical operating conditions.

Essential Regulatory References

Design and manufacturing shall comply with the following construction codes and standards:

ASME B31.3: Process Piping (for application in process piping systems).

ASME BPVC Section VIII – Division 1 & Division 2: Rules for Construction of Pressure Vessels and Alternative Rules (for the calculation of hubs and clamps).

NACE MR 0175 / ISO 15156: Materials for use in H₂S-containing environments in the oil and gas industry (for sour service applications).

In an industrial environment increasingly focused on standardization, efficiency, and operational continuity, Clamp Connectors Ω-Lock are positioned as a reliable solution aligned with the requirements of highly structured projects. Compliance with the principle of interchangeability, combined with rigorous design criteria and high manufacturing quality, enables effective integration into both existing systems and new installations.

Clamp Connectors Ω-Lock represent a sound and responsible choice, supporting balanced technical and commercial decisions, reducing operational complexity, and ensuring consistent performance over time.