Composition

- PAN carbon and expanded graphite yarn

- Graphite powder impregnation

- Corrosion inhibitor

Characteristics

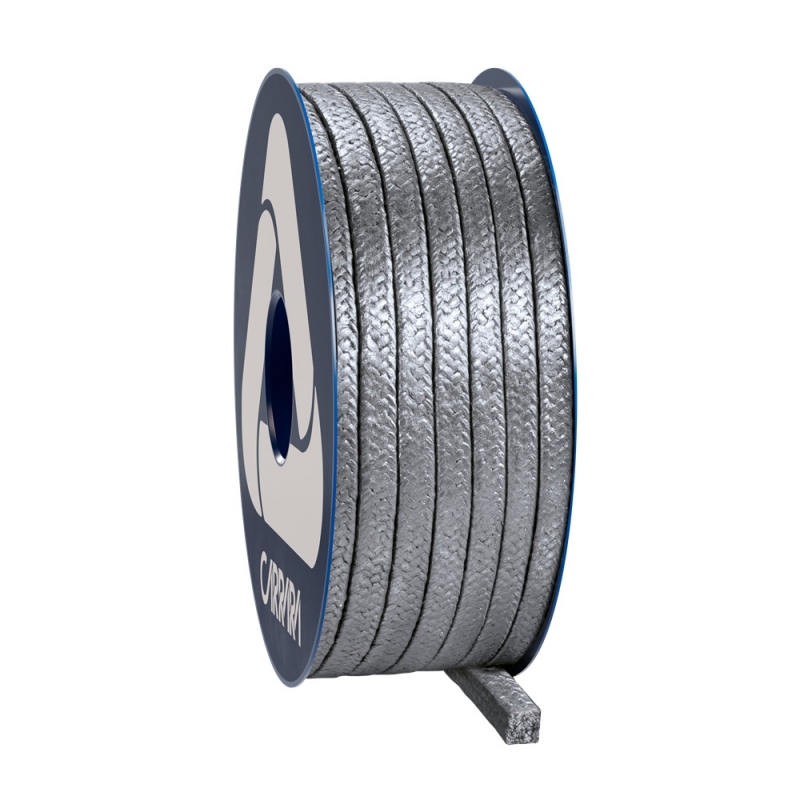

The GR8048 braid is the ideal solution to ensure maximum sealing of industrial valves and pumps, thanks to the combination of carbon fiber and expanded mineral graphite yarns. The special solution based on pure graphite powder and corrosion inhibitor applied to the braid minimizes fugitive emissions, increasing the sealing level. The GR8048 braid is highly elastic and reliable at high temperatures, and thanks to the graphite yarn with continuous PAN carbon fibers on the corners, it offers great resistance against extrusion and wear. Easy to install in the stuffing box, the expanded mineral graphite GR8048 braid is the ideal solution for multiple industrial applications.

Applications

The graphite packing GR8048 is equipped with a double yarn, making it particularly versatile and suitable for various industrial applications. Thanks to its high elasticity and reliability at high temperatures, it can be used in high-pressure and high-temperature static services, such as in sealing valves and pumps in chemical and energy processes. Moreover, thanks to its resistance to extrusion and wear, it can be successfully applied in dynamic services, such as those of soot blowers and diathermic oil systems. The graphite packing GR8048 can be used with all non-oxidizing fluids compatible with graphite, ensuring a high level of sealing and minimizing fugitive emissions. The graphite braid GR8048 represents the ideal solution for those seeking a versatile, reliable, and resistant product to use in various industrial applications, ensuring high performance in every operational context.