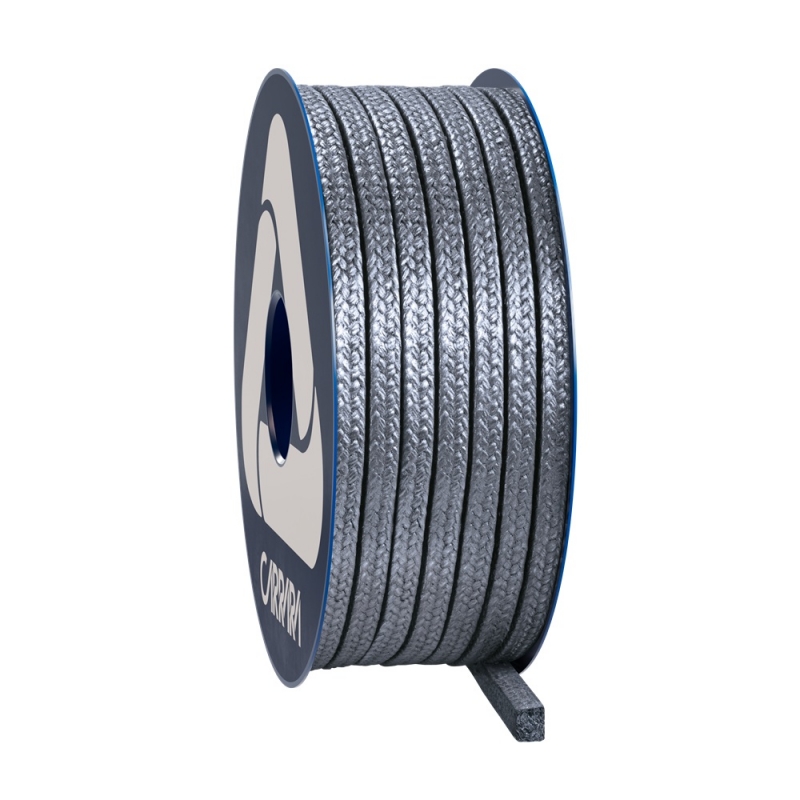

Composition

- PAN yarns nickel-alloy wire

- Graphite Powder

- Passive Inhibitor of Corrosion

Characteristics

GR8800R is a product with excellent performance, made with PAN graphite yarn, ensuring high-level performance in all’industrial applications, except for strongly oxidizing fluids. One of the main features of GR8800R is its high elastic recovery that does not regress with aging, allowing the product to maintain its sealing properties over time, ensuring long-lasting durability and constant safety. Additionally, GR8800R has been specially impregnated with a passive corrosion inhibitor that preserves the stems from corrosion. Thanks to these attributes, GR8800R is a high-quality product that combines excellent performance with safety characteristics.

Applications

Carbograph GR8800R is the ideal gasket for service valves used in high-temperature industrial steam, fluid, and gas applications. Thanks to its versatility, achieved through the use of PAN yarn, this packing can be successfully used with all chemicals except for highly oxidizing ones, and is one of the easiest and fastest solutions to install. However, it is recommended to avoid using this gasket with combustion gas and hot air over 450°C. With Carbograph GR8800R, you can ensure maximum safety and durability for your industrial valves.