Composition

PAN carbon yarns with graphite powder, MoS2 lubricants.

Characteristics

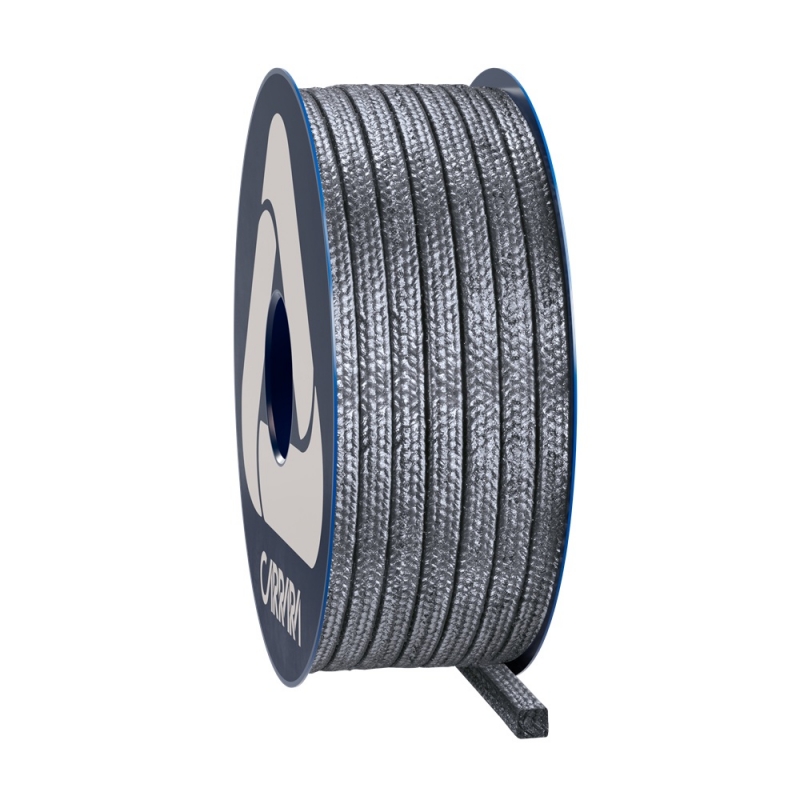

The compression packing C8100 is braided with pure carbon PAN yarns. This material gives to the packing a considerable flexibility and elasticity when installed for sealing the pumps. This packing is impregnated with high temperature lubricants loaded with graphite powder and MoS2 to reduce the friction.

Applications

The C8100 packing is specific for high temperature dynamic applications of fluids non oxidizing and compatible with the PAN yarns.