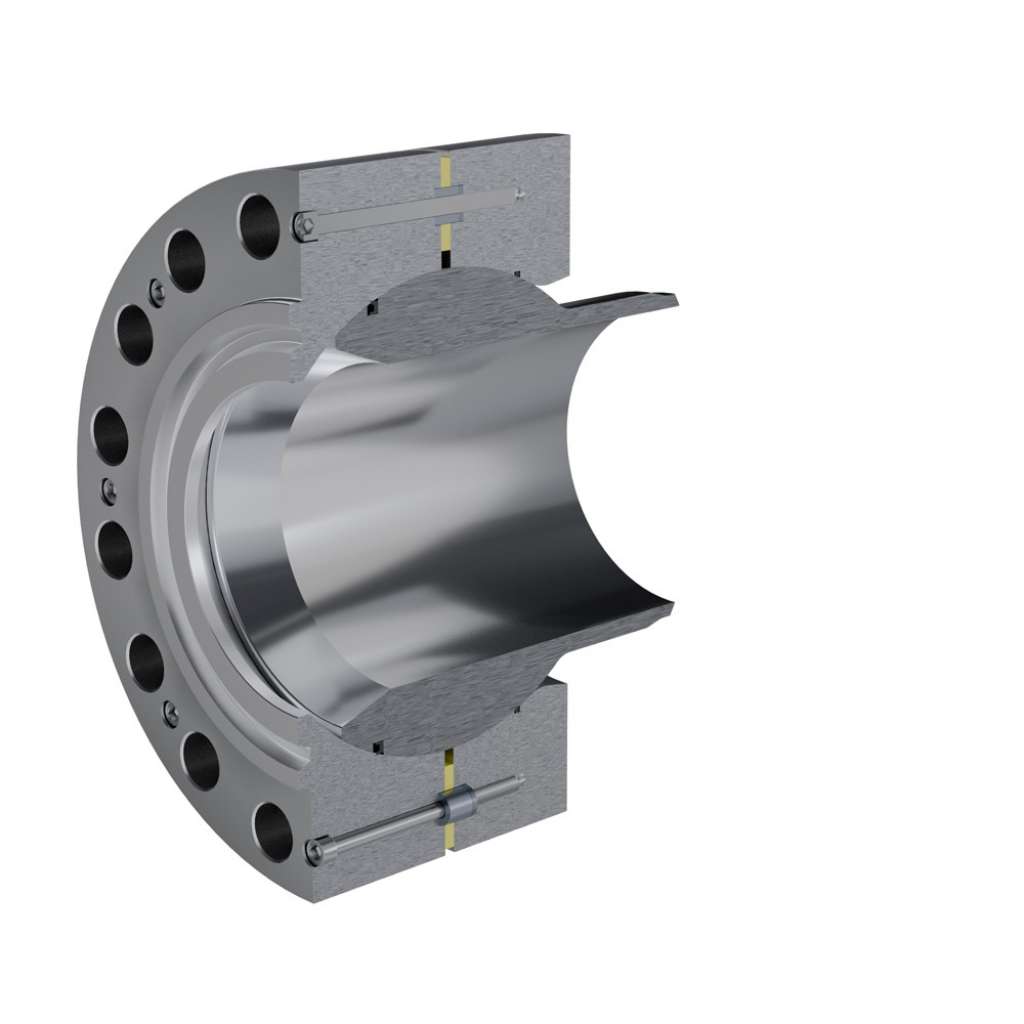

The MBC – Misalignment Ball Connector is an innovative joint designed for pipeline and piping systems where it is necessary to compensate for misalignments between line sections.

Thanks to its hermetic sealing, the MBC significantly reduces installation time for connections, especially in subsea environments, while ensuring superior performance and versatility compared to welded joints or conventional flanges.

Although primarily developed for subsea applications, the MBC is also a reliable solution for surface installations, wherever pipeline misalignment may compromise proper joint assembly.

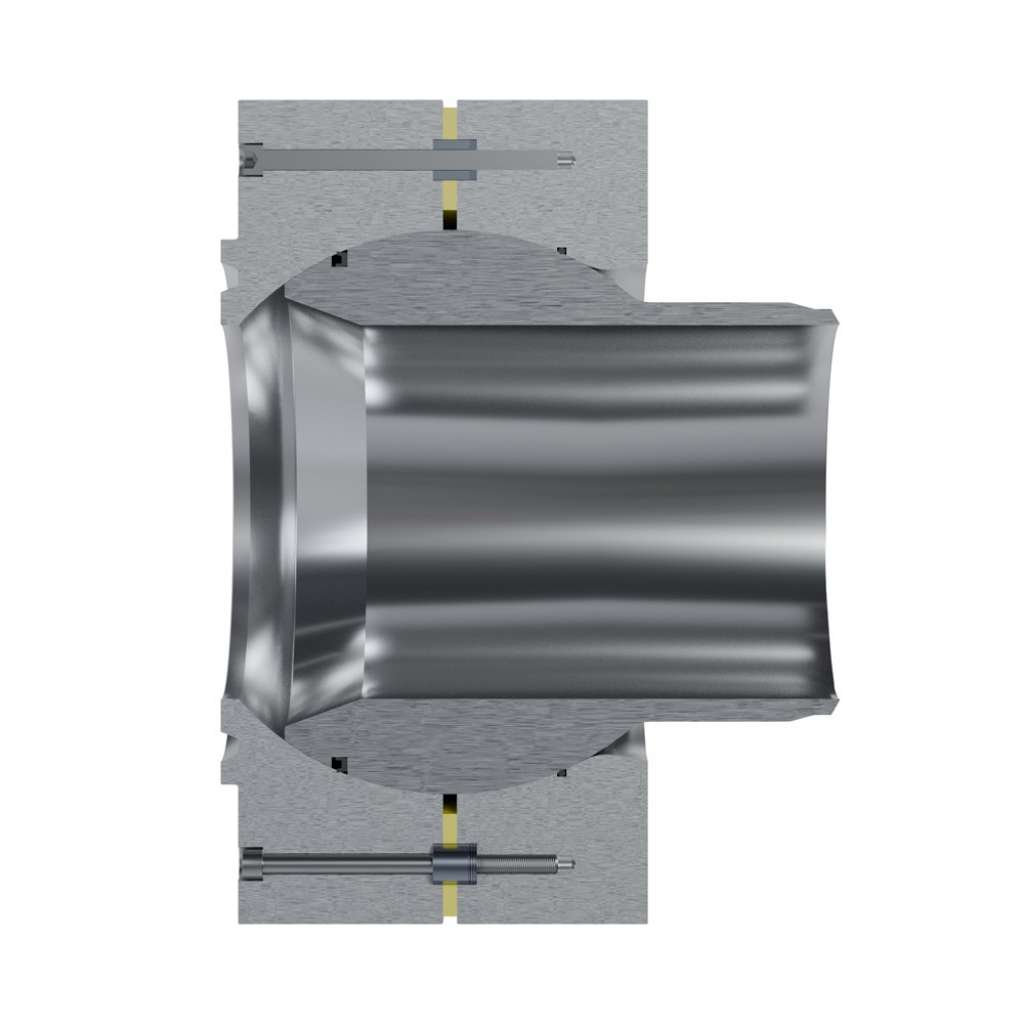

The spherical ball joint design with metal-to-metal sealing on the RTJ flange allows compensation of up to ±10° misalignment on any axial plane relative to the pipeline axis (20° total), without compromising sealing capacity.

Bolt tightening locks the spherical element into the flange seat, transforming the assembly into a rigid, static, and completely leak-tight connection.

The connection is engineered according to ASME sealing criteria for RTJ (ring-joint) flanges and ensures:

-

Constant sealing at any angle of misalignment within the admissible range

-

Resistance to external bending loads during operation

-

Reliability at maximum operating pressures