Composition

- PAN graphite yarns

- Graphite Powder

- Passive Inhibitor of Corrosion

Characteristics

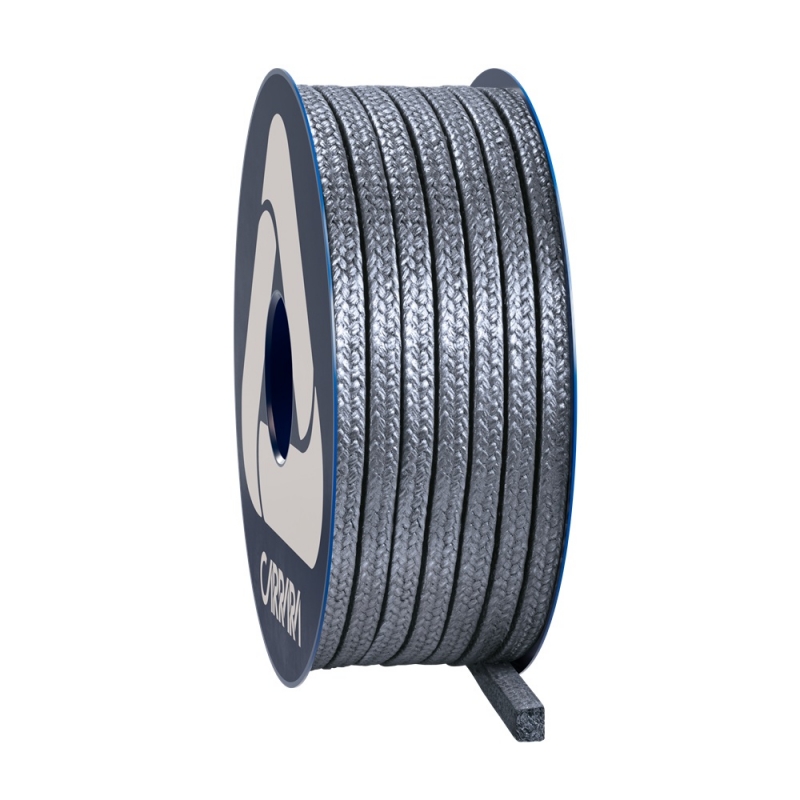

The GR8800 gland packing is a high-quality solution for multiple industrial applications. Thanks to its three-phase impregnation with graphite powder and inorganic corrosion inhibitor, the gland packing is able to minimize the risk of stem corrosion and ensure high resistance to high temperatures. The PAN graphite yarn used in the gland packing also offers great elastic recovery that does not regress with aging, ensuring exceptional performance in all’industrial applications, except those that involve the use of highly oxidizing fluids.

Applications

GR8800 is a high-quality graphite suitable for multiple applications, such as industrial valves for steam, hydrocarbons, and petrochemical products, pumps for boiler feedwater, and soot blowers. Additionally, it can also be used with heat transfer oils. However, the use of this graphite should be avoided in applications involving strong oxidizing agents or in the presence of exhaust gases or air above 450°C, as its efficiency is compromised under such conditions. In general, GR8800 represents a reliable and efficient choice for numerous industrial applications where high-quality and resistant materials are required.