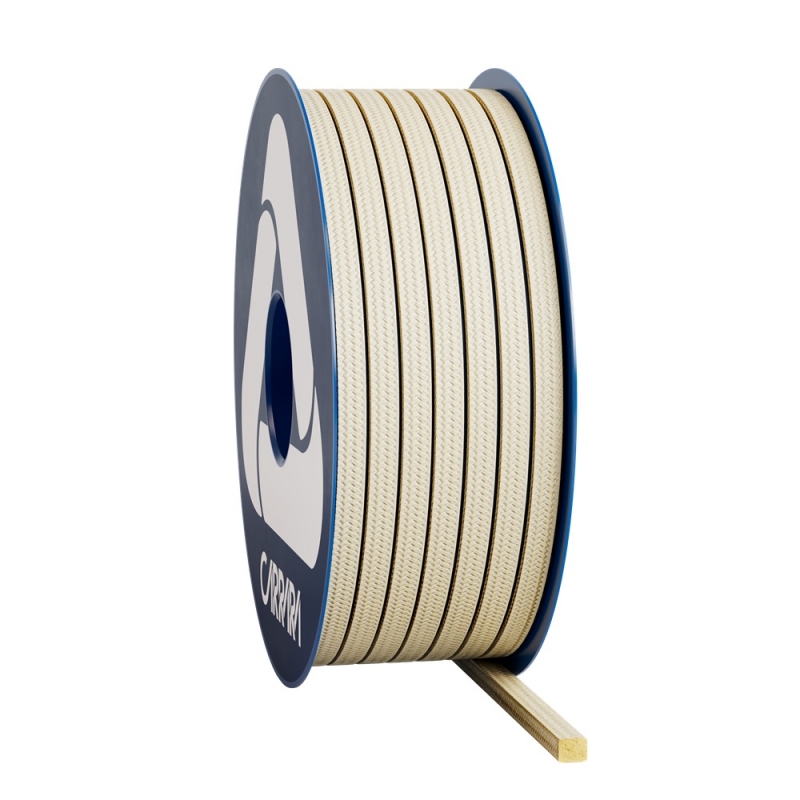

Composition

- Long fiber aramid yarn

- PTFE impregnation

- Silicone-free lubricant

Characteristics

KD6604 is a special packing made entirely of long fiber discontinuous aramid yarn. The characteristic of this yarn is its high toughness and abrasion resistance. The impregnation process takes place in three stages: one on the yarn, a second during braiding, and the third on the surface of the braided product. KD6604 is a 100% aramid fiber braid that is excellent for versatility and safety of use. It can be applied to any type of pump, mixer, or agitator in the paper, food, and industrial sectors.

Applications

KD6604 is an aramid packing for pumps used for lifting water, wastewater, and slurry services. KD6604 is a universal braided packing that is easy to use and applicable in any dynamic context where resistance must be combined with maximum flexibility. It can be installed on mixers and in many low-speed dynamic applications in the absence of fluids such as horizontal ovens. KD6604 is the braid made with long fiber aramid yarn. PTFE impregnation and lubricants are carried out in three stages: on the yarn, during braiding, and on the body of the braid.