Composition

-

100% Phenolic matrix yarn

-

PTFE impregnation

-

Silicone-free lubricant

Characteristics

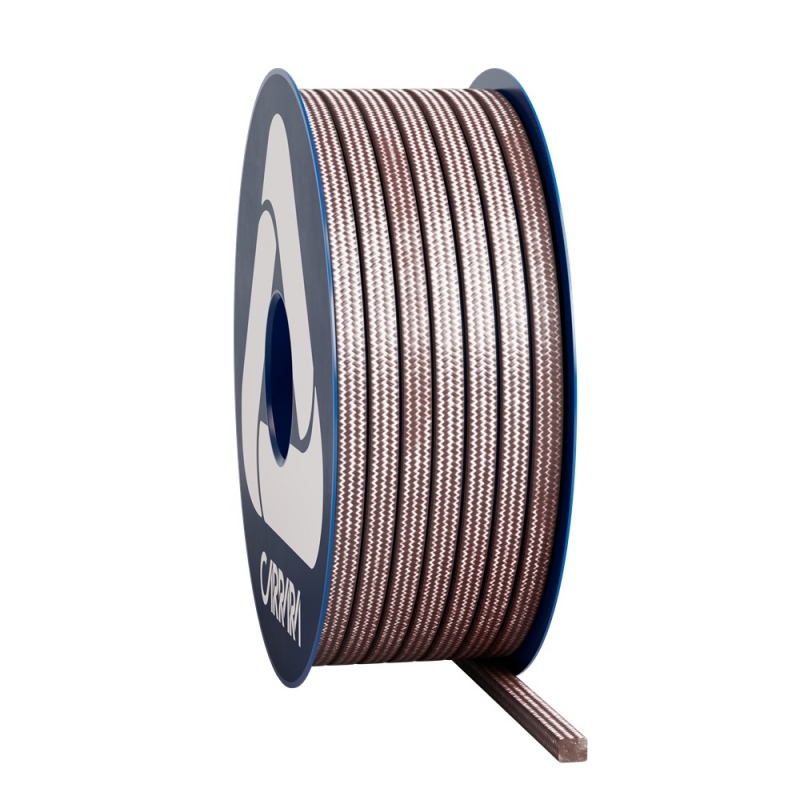

N1304 is a pump packing manufactured with the Kynol® yarns, a new generation of heat resistant synthetic fibers. This fiber has the same resistance than the aramid fiber but with the chemical inertness and the coefficient of friction similar to the PTFE. For best results each strand is previously lubricated with PTFE and with a special lubricant break-free silicone. N1304 is a packing suitable for dynamic applications with abrasive fluids and severe pH conditions. Compatible with weak acids and bases, water, steam, solvents and the packing is more efficient to combine longevity of service and quality seal.

Applications

Packing suitable for slurry pumps.