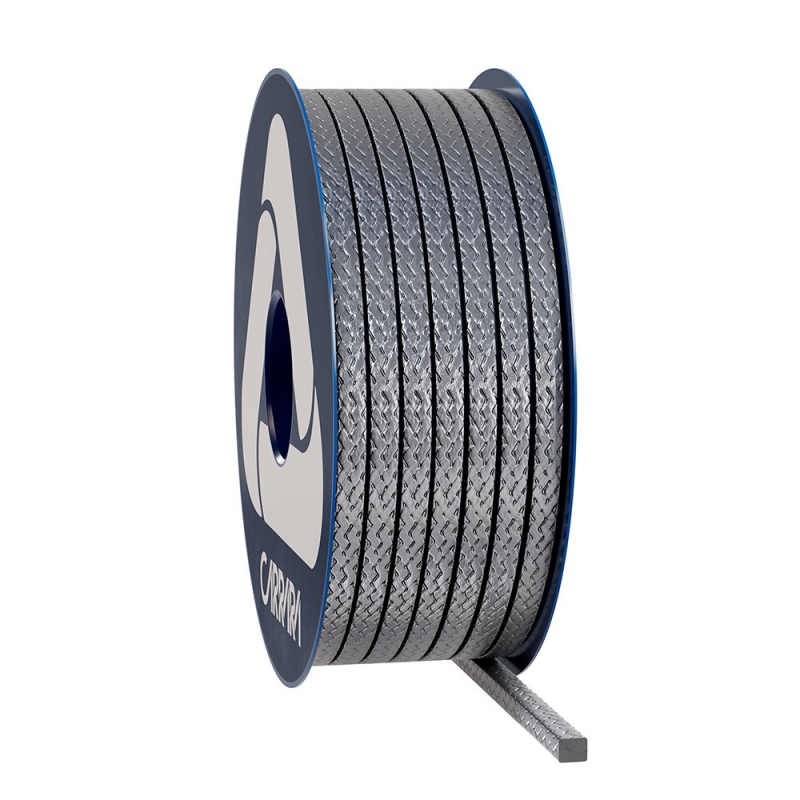

Composition

- Expanded mineral graphite

- Special reinforcement nickel-alloy

- Impregnation with graphite-based compound and special components

Characteristics

GR80SGR is composed by expanded graphite strands with a special reinforcement that increases its strength and durability. This expanded graphite packing offers superior performance at high temperatures and very low weight loss during operation, ensuring reliable sealing over time. GR80SGR complies with EN14772 - section 6.7 requirements, ensuring maximum safety in high-pressure applications. With its low coefficient of friction, this expanded graphite packing ensures effective sealing even in extreme conditions. In addition, the Low Emission ISO 15848 certification makes GR80SGR the ideal solution for applications that require low environmental impact and high energy efficiency. With its reliability and ability to maintain elastic and sealing properties over time, GR80SGR minimizes the need for maintenance and saves long-term time and costs.

Applications

The GR80SGR packing is specially designed for low emission industrial valves and those operating under high pressure and temperature conditions. Thanks to its excellent sealing properties, this expanded graphite packing represents the ideal choice for applications that require a high level of reliability and safety, ensuring resistance to reciprocal dynamic stresses, such as those typical of valve opening and closing services. This expanded graphite packing offers maximum flexibility of use, adapting to different application needs and ensuring high performance even in extreme conditions.