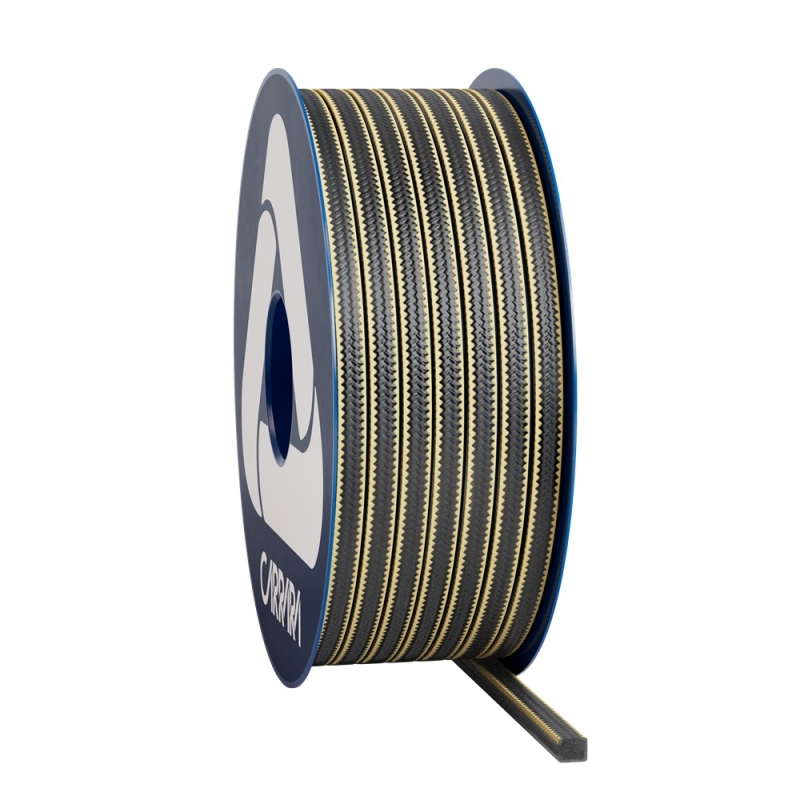

Composition

GORE® egPTFE yarns

Aramid yarns

Characteristics

The packing style GF4600KS is braided with pure GORE® egPTFE yarns and aramid yarns on the corners. the GORE® yarn consists of expanded PTFE with encapsulated graphite, without any lubricants. The packing GF4600KS offers great resistance to extrusion and wear thanks to its ultra-dense body and its very low coefficient of friction.

Applications

The compression packing style GF4600KS is recommended for high pressure reciprocating pumps and it is suitable for all industrial fluids in the pH range 3 ÷ 12 which are compatible with the aramid, graphite and PTFE. The braided packing style GF4600KS has been designed for the huge industrial reciprocating pumps with great head. The sealing of this type of pumps is very stressed due to the high pressure and often to the high temperature too. The packing GF4600KS meets high quality standards to ensure safety and long service life.