Composition

- P.A.N. carbon yarns with nickel-alloy micro-filament

- Pure colloidal graphite

- Inorganic inhibitor of corrosion

Characteristics

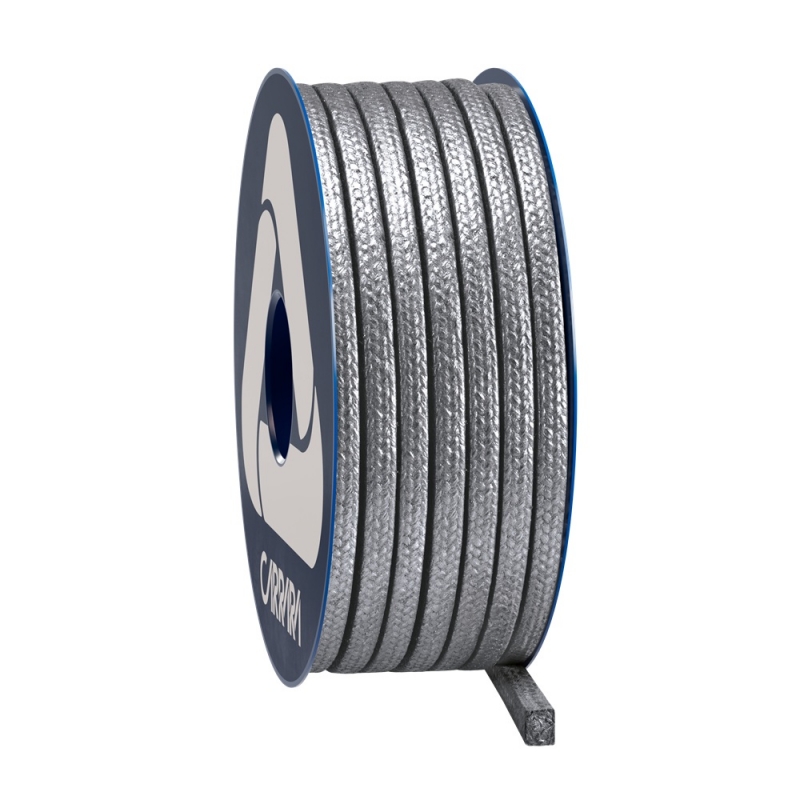

GR8807 INCOBRAID® is made with discontinuous PAN carbon yarns, reinforced with discontinuous metallic micro-filaments. The sealing rings are highly elastic due to a special impregnation process that is carried out in three stages: on each yarn, during braiding, and on the packing body with a mixture rich in inorganic corrosion inhibitors and colloidal graphite. GR8807 INCOBRAID® is a special packing that exhibits extraordinary elastic recovery and excellent extrusion resistance. It has been designed for H.P./H.T. valves that are frequently operated in steam, hydrocarbon, and chemical service.

Applications

GR8807 INCOBRAID® is an excellent material for sealing industrial valves under high temperature and high-pressure conditions. Specifically, it is particularly suitable for use in power plants, refineries, and petrochemical plants, where extreme conditions require materials that can deliver superior performance. Graphite packings are characterized by their excellent elasticity, which enables them to adapt to changes in pressure and temperature over time without compromising the seal of the system.