Composition

Rayon graphite yarns high carbon content C>99,50%

Impregnated with colloidal graphite

Passive inhibitor of corrosion

Characteristics

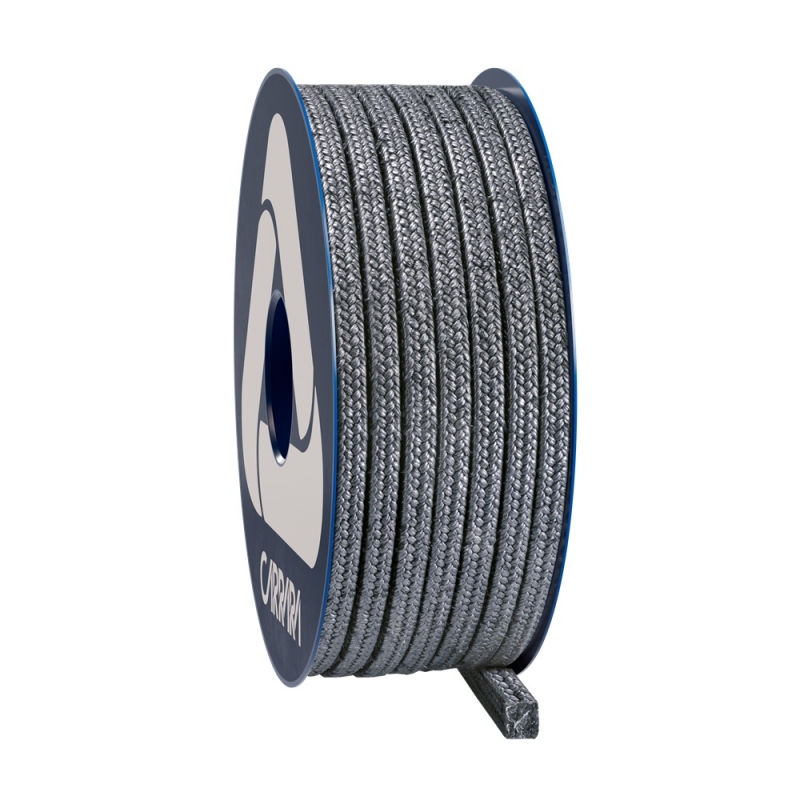

GR8888 is a special Rayon-based high carbon content graphite packing. The yarn is highly flexible, elastic and completely insensitive to thermal cycles, resisting to the thermal stresses without damage. In addition, all threads are impregnated with a special mixture of colloidal graphite enriched with a corrosion inhibitor to ensure maximum stem’s protection. GR8888 packing maintains its mechanical properties and its original shape even under conditions of high thermal stress, without undergoing any loss of weight or volume. Thanks to these characteristics, GR8888 proves to be an ideal choice for applications that require reliable and durable sealing performance over time.

Applications

The GR8888 packing has been designed to withstand the most challenging environmental conditions, making it a versatile and reliable solution for valves and pumps in multiple industrial applications. The GR8888 is suitable for all fluids, except strong oxidants, combustion gases, and hot air above 450°C. The packing withstands high temperatures without losing weight and volume, maintaining high elastic and mechanical properties, making it an ideal choice for demanding operating environments. In summary, the GR8888 packing represents an excellent solution for ensuring sealing and reliability in various industrial applications.