Composition

- Discontinuous aramid fibres

- PBI yarns on the corners

- PTFE and lubricant impregnation

Characteristics

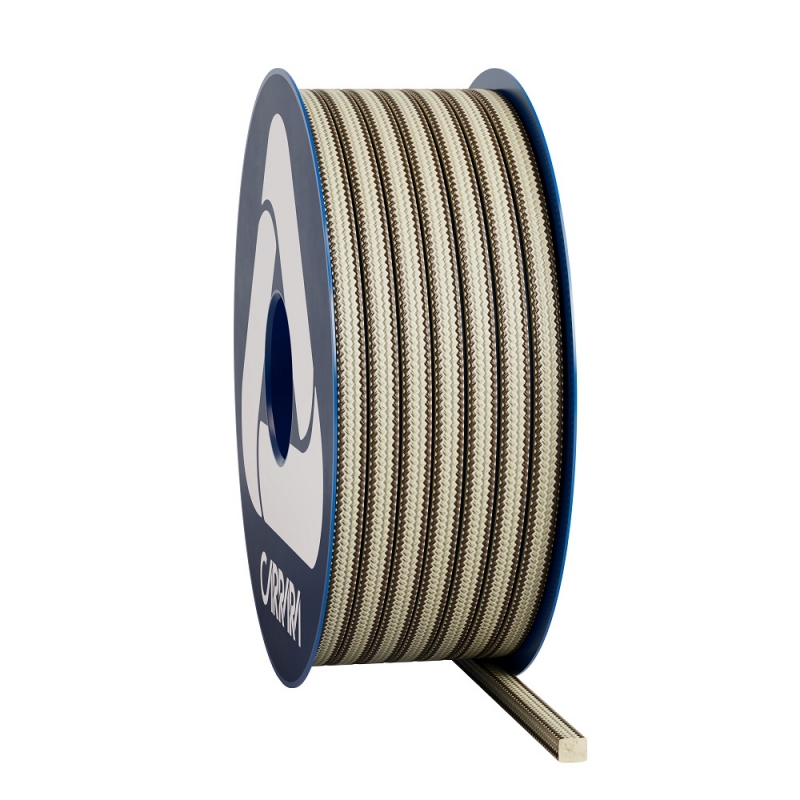

Special compression packing made with aramid yarns; corners are further reinforced using PBI yarns. The impregnation is done in three stages: first on the yarns, secondly during the braiding and thirdly on the surface of the finished product. The special aramid gland compression packing KD6605 DINACOMB® is made with aramid and PBI yarns that reduces the coefficient of friction. The impregnation, that comes in three steps, on the yarns, during the braiding and on the body, gives to the packing great flexibility and wear resistance.

Applications

KD6605 is a highly performing sealing product, ideal for use in pumps, pulpers, and mixers used in various industrial sectors, such as paper, sugar, and cement. This aramid fiber packing ensures an excellent level of sealing, allowing the control of leaks and preventing fluid leakage. This product has been specially designed to reduce the frequency of maintenance operations, thanks to its high resistance and reliability. In this way, maintenance costs are reduced and plant productivity is increased. KD6605 is the ideal choice for those looking for a high-quality sealing solution that guarantees excellent performance, long life, and low maintenance costs.