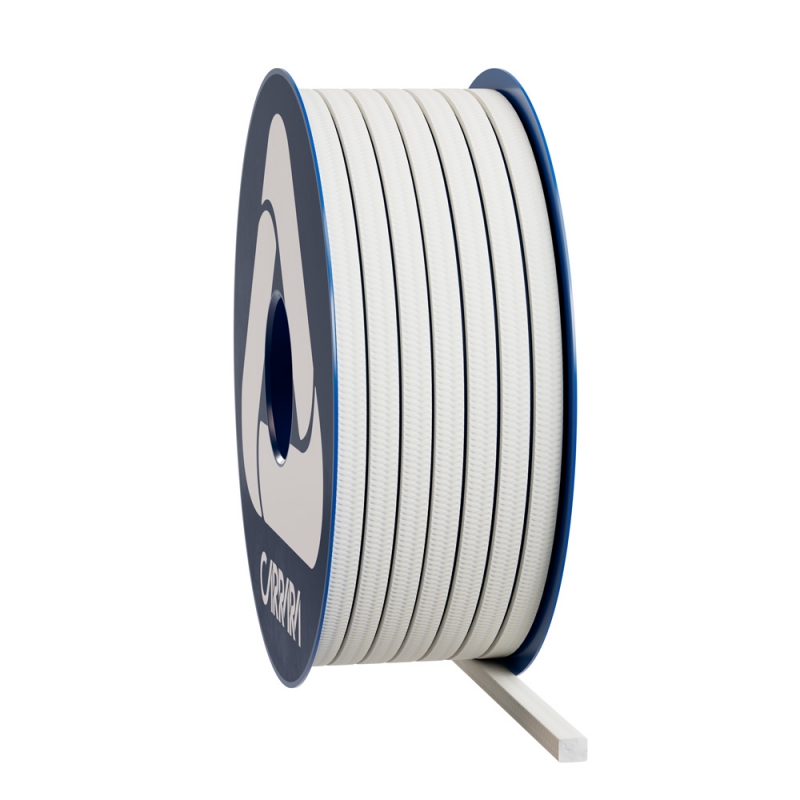

Composition

- Viscose technical yarns

- Dispersion of PTFE

- Inert lubricant

Characteristics

The fibers of the compression packing B1204 have an excellent chemical resistance (pH 1 ÷ 14). For this reason B1204 can be used both in the cellulose production process, where a greater chemical resistance is required, and in the other general services of the paper mill. B1204 is extremely soft thanks to the exclusive three-stage lubrication with PTFE which further reduces the friction of the packing. B1204 Dinawhite is a universal packing for paper mills that uses a composite fiber with very high mechanical resistance (tensile strength 27,000 Kg / cm2) with a low coefficient of friction, which reduces the abrasion up to 1 / 10 of the aramid fibers, increasing the life cycle of the braided packing.

Applications

The packing B1204 is specific for dynamic services with abrasive products and slurry pumps.

- Simple to use, easy to cut and install

- It allows a better regulation of the minimum lubrication during the exercise

- It is stronger than aramid fiber packing for high speed abrasive applications

- It is white and therefore eliminates the risk of contamination

- It does not wear out the shaft sleeves