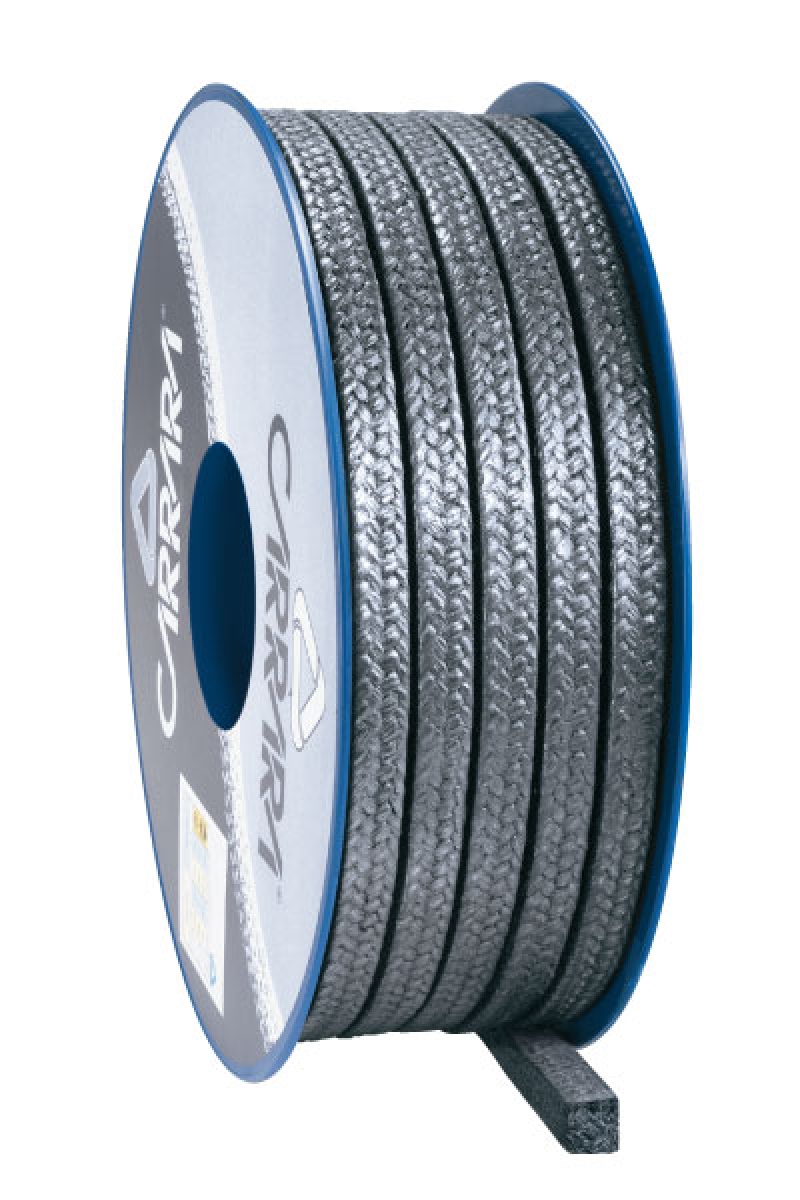

Composition

- PAN spun graphite yarns nickel-alloy wire

- Colloidal Graphite

Characteristics

The graphite gland packing GR8000R is the ideal choice for applications that require superior wear resistance, thanks to its Nickel-Alloy metal reinforcement. The reinforced continuous graphite PAN fiber yarn guarantees superior performance in all static sealing applications in industrial settings. The GR8000R gland packing ensures high reliability, safety, and an excellent level of quality thanks to its ability to maintain a high elastic recovery over time. The GR8000R gland packing is suitable for use with all industrial fluids and gases except for strong oxidizers. Thanks to the metal reinforcement, the GR8000R gland packing is able to withstand higher pressures than the standard GR8000 version. Its flexibility and ease of installation make it a popular choice among industry professionals.

Applications

The graphite packing GR8000R is highly versatile and suitable for all static high-temperature applications in various industrial sectors. Thanks to its ability to withstand various industrial fluids and gases, it can be used with almost all types of products except for strong oxidants. The GR8000R packing is also available in the GR8000 version without Nickel-Alloy metal reinforcement, offering the possibility to choose between two options depending on the specific needs of the application. Its high resistance and reliability make it ideal for a wide range of applications, ensuring excellent and long-lasting performance over time.