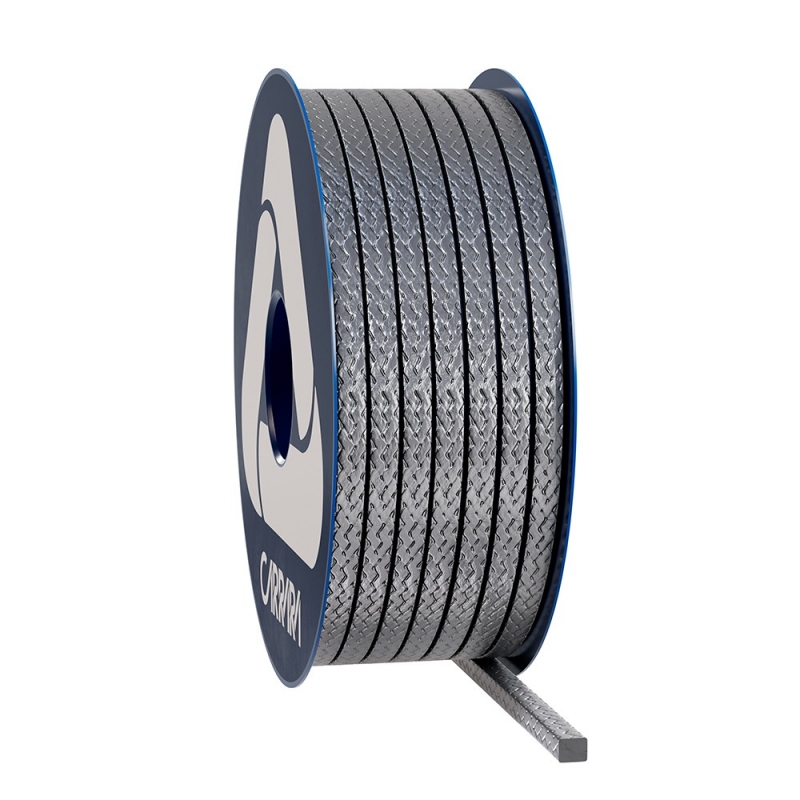

Composition

- Pure mineral flexible expanded graphite strands

- Nickel-Alloy reinforcement

- Impregnation with colloidal graphite

Characteristics

The GR81SGR packing is made with expanded mineral graphite with a special reinforcement that ensure high extrusion resistance and excellent elastic return. Thanks to its particular structure, GR81SGR maintains its performance and elastic properties over time, making it an ideal choice for the most demanding industrial applications. GR81SGR is highly resistant to wear and abrasion and has good thermal conductivity, making it suitable for high-temperature applications. In summary, GR81SGR is an effective and cost-efficient solution to ensure the sealing and reliability of industrial equipment in demanding operating environments.

Applications

The GR81SGR graphite packing is specifically designed for use in high temperature and high pressure industrial valves. Thanks to its resistance to extrusion and elastic recovery, this packing offers reliable and long-lasting performance even in demanding operating environments. In particular, GR81SGR is ideal for reciprocating dynamic applications at low speeds, where a reliable and wear-resistant seal is required. With its advanced technical features, GR81SGR is an excellent choice for ensuring the safety and reliability of industrial valves in a variety of applications.