Composition

High carbon content flexible graphite yarns.

Characteristics

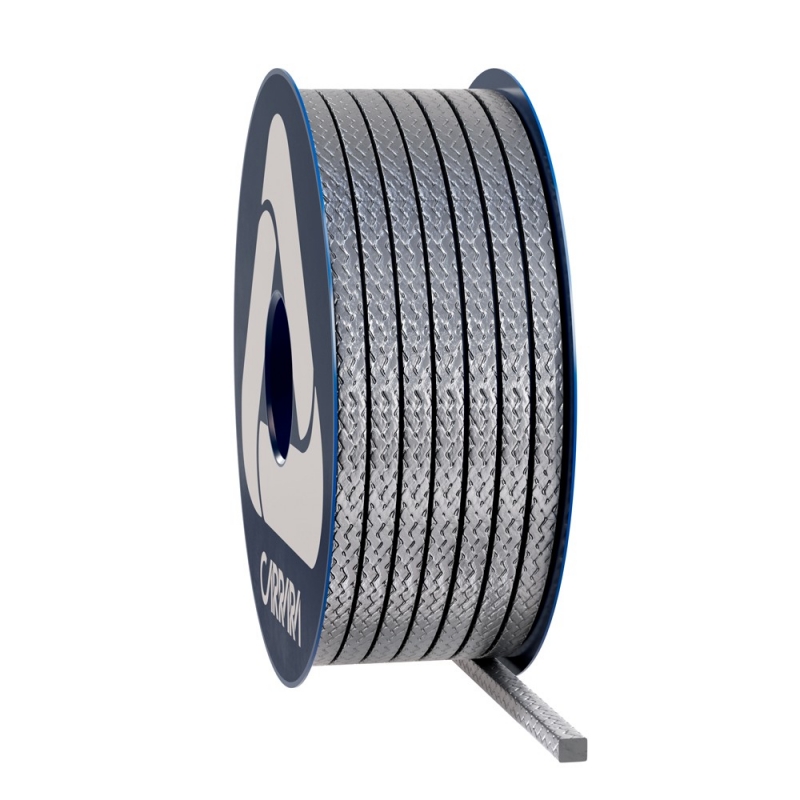

GR48 is a high-quality expanded mineral graphite packing made of high carbon content expanded graphite yarns. Its ability to withstand extreme temperatures and high pressures, combined with low thermal conductivity, make it an ideal choice for many industrial applications, where ease of cutting and installation is combined with extraordinary versatility. Thanks to its high-quality construction and great reliability, the expanded mineral graphite packing GR48 is a winning choice for those looking for a versatile and high-performance product for their industrial needs. Additionally, GR48 packing is also available in the reinforced version GR48R.

Applications

The flexible mineral graphite packing GR48 is an ideal solution for sealing industrial valves of all types, thanks to its extreme flexibility and versatility. Due to the high carbon content in the expanded graphite yarns, this packing is able to resist multiple industrial fluids and gases, with the exception of strong oxidizers. It can operate at a maximum pressure of 100 bar without the use of anti-extrusion rings. In the case of dynamic seals, however, it is recommended to use it with the help of anti-extrusion rings to ensure even better performance and extend its lifespan.