Composition

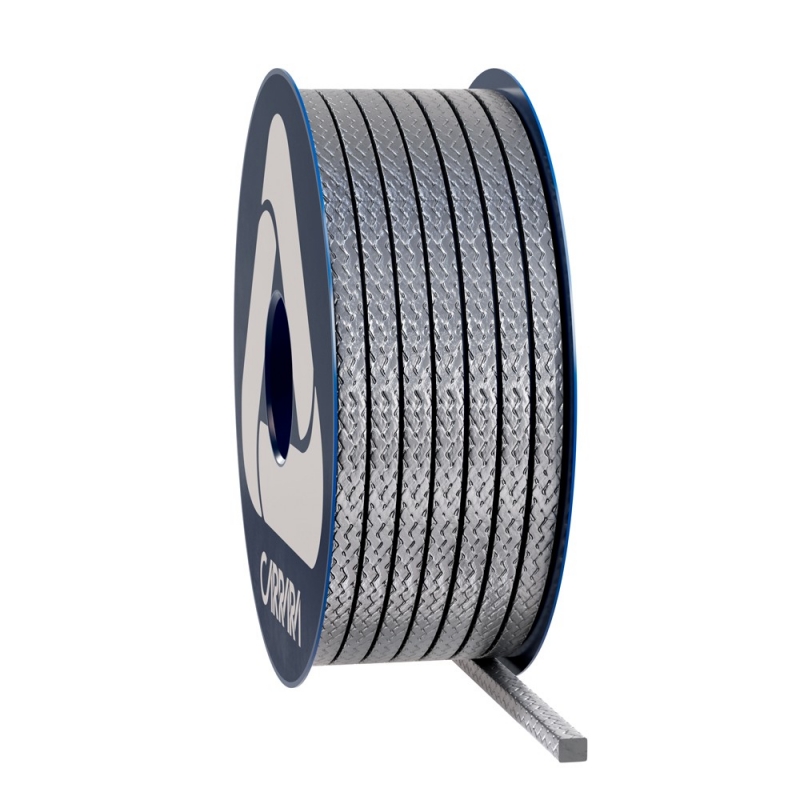

Pure high carbon content expanded graphite yarns reinforced with InconelTM wire.

Characteristics

The expanded graphite packing GR48R is a versatile and high-performing solution for many industrial applications. Made with expanded graphite yarns with high carbon content and reinforced with InconelTM, it can withstand high temperatures and pressures, as well as multiple industrial fluids and gases, except for highly oxidizing ones. Thanks to its easy cutting and installation, this universal packing is an ideal choice for sealing valves of all types. Additionally, the GR48R packing is also available in the non-reinforced version GR48, which still offers excellent performance in many industrial applications. With GR48R and GR48, you can ensure maximum safety and reliability for your industrial seals.

Applications

The expanded graphite braid GR48R is specifically designed to ensure perfect sealing on industrial valves of all types, with the ability to use various fluids and gases, excluding only highly oxidizing ones. Thanks to the high carbon content present in the expanded graphite yarns and the nickel-alloy metal reinforcement, this braid guarantees greater resistance and durability over time compared to the non-reinforced version GR48. However, to achieve optimal performance in the case of dynamic seals, it is recommended to use GR48R with the help of anti-extrusion rings. It is important to note that the maximum pressure for use in valves should not exceed 100 bar in the absence of anti-extrusion rings. In any case, the flexible graphite braid GR48R represents an ideal solution for industrial needs that require reliability, resistance, and versatility.