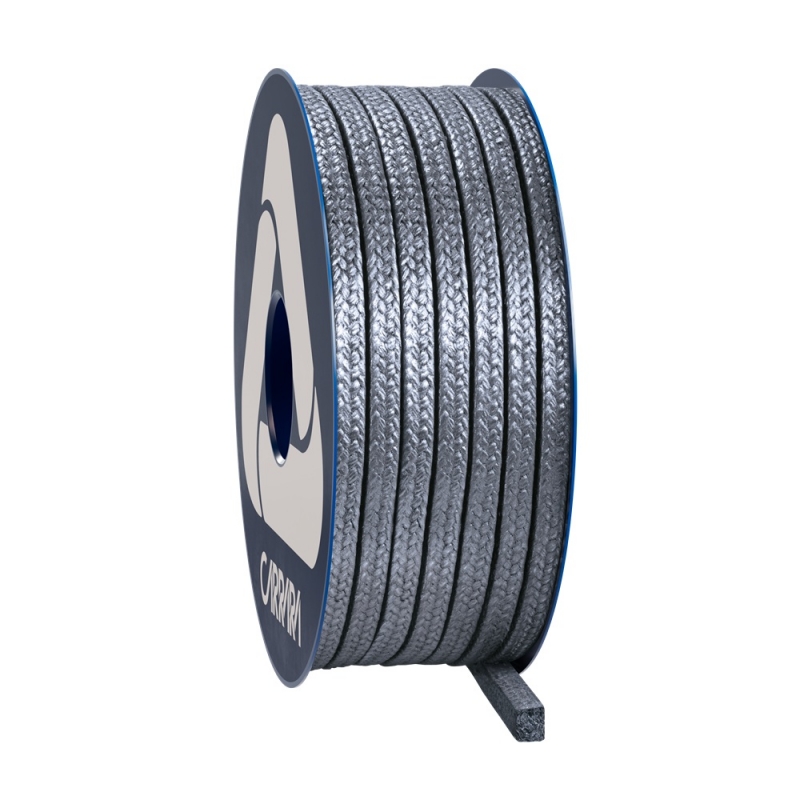

Composition

- Carbon yarns

- Graphite Powder

Characteristics

The graphite packing GR8000, thanks to its composition with continuous PAN graphite fiber yarn, offers a winning combination of mechanical strength and sealing properties. Thanks to this structure, the GR8000 packing is able to ensure excellent sealing on valves and pumps at high pressures, maintaining a high elastic recovery that does not undergo alterations over time. The yarn in graphite with PAN continuous carbon fibers, present in the GR8000 packing, also provides greater resistance to extrusion, wear, and mechanical damage. Thanks to its versatility, the GR8000 packing can be used in multiple industrial applications, both static and dynamic, with non-oxidizing fluids and compatible with graphite.

Applications

The graphite packing GR8000 is suitable for a wide range of industrial applications, primarily designed for high temperature and pressure static seals, but can also be used in many dynamic applications. The GR8000 packing can be used with all industrial fluids and gases, except for strongly oxidizing ones. Additionally, for applications requiring greater mechanical strength, a reinforced version GR8000R with Nickel-Alloy metallic reinforcement is available. The graphite packing GR8000 provides high reliability thanks to its high elastic recovery, which does not deteriorate over time, due to the continuous PAN graphite fibers. Its extreme versatility, ease of cutting and installation make it an ideal solution for various sealing needs in the industrial field.