Characteristics

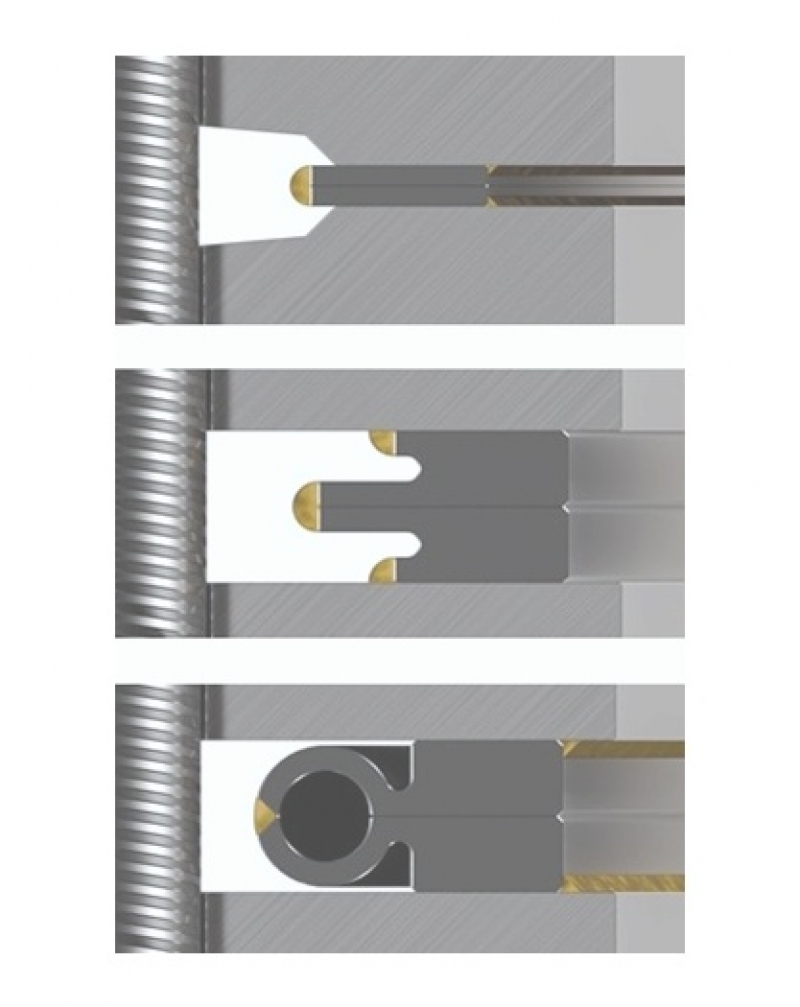

A weld ring gasket, commonly also known as a lip seal weld ring gasket, consists of a pair of metallic rings. Each ring is initially welded to the flange surface. During joint assembly, the two rings are then welded together along the outer edge, thus completing the seal.

| Code | Description |

|---|---|

|

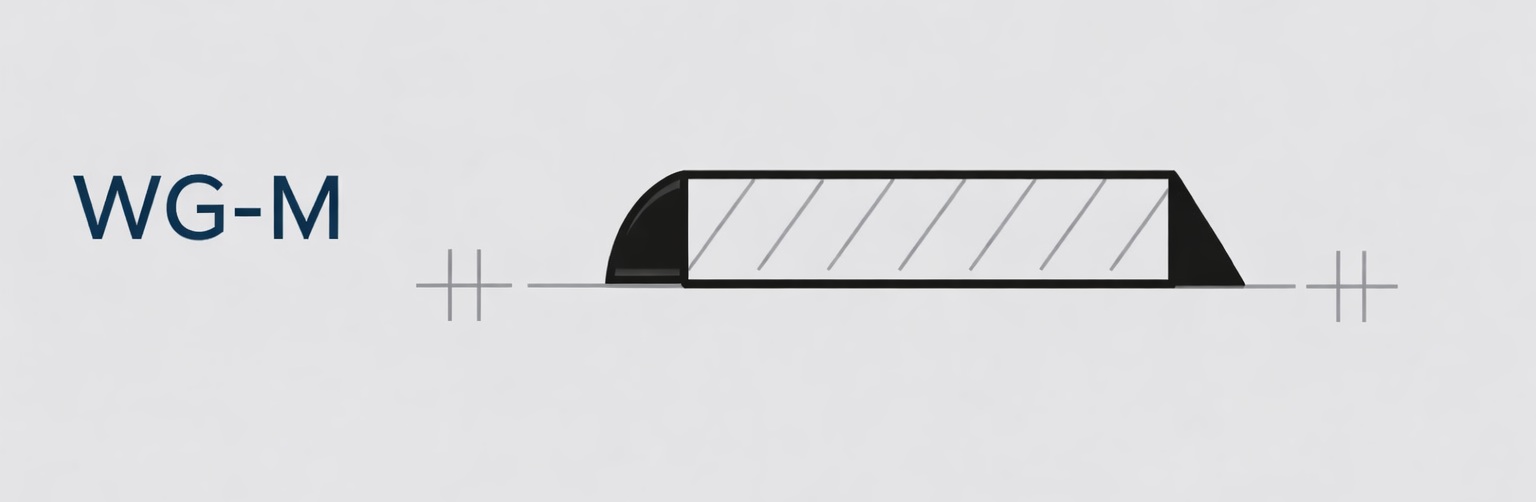

Basic solution for applications where the space between flanges is limited. |

|

Typical thickness: 4 mm - Re-weld times: up to 5 - Radial compensation: 0.3 mm |

|

|

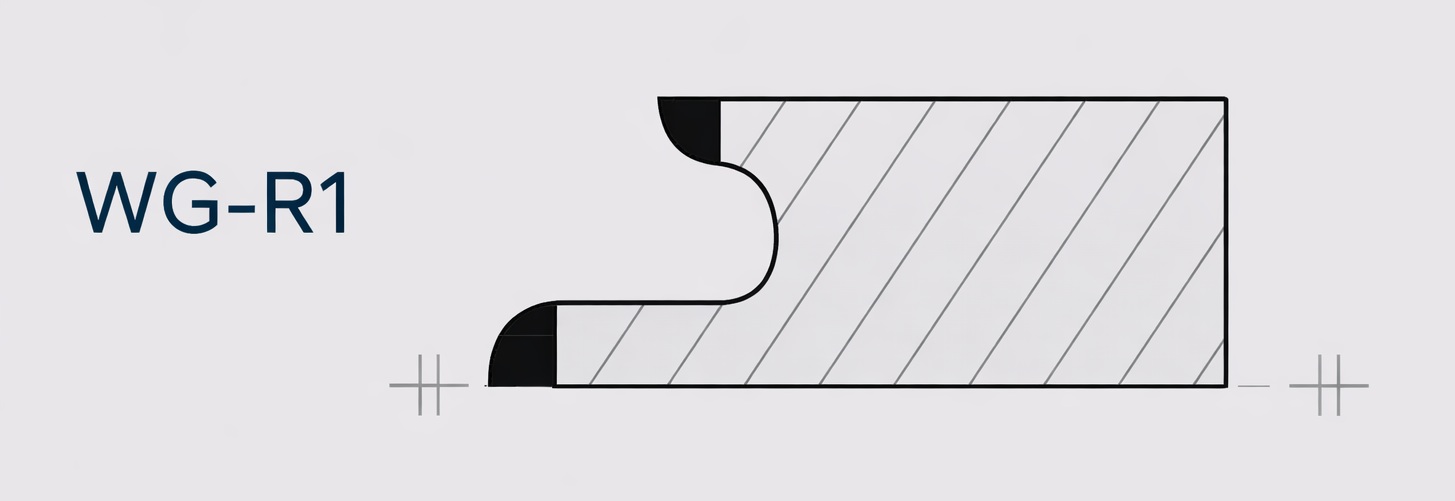

Similar to type WG-M, but with the possibility of both external and internal weld beads, which greatly facilitate installation (*). |

|

Typical thickness: 15 mm - Re-weld times: up to 5 - Radial compensation: 0.1 mm |

|

|

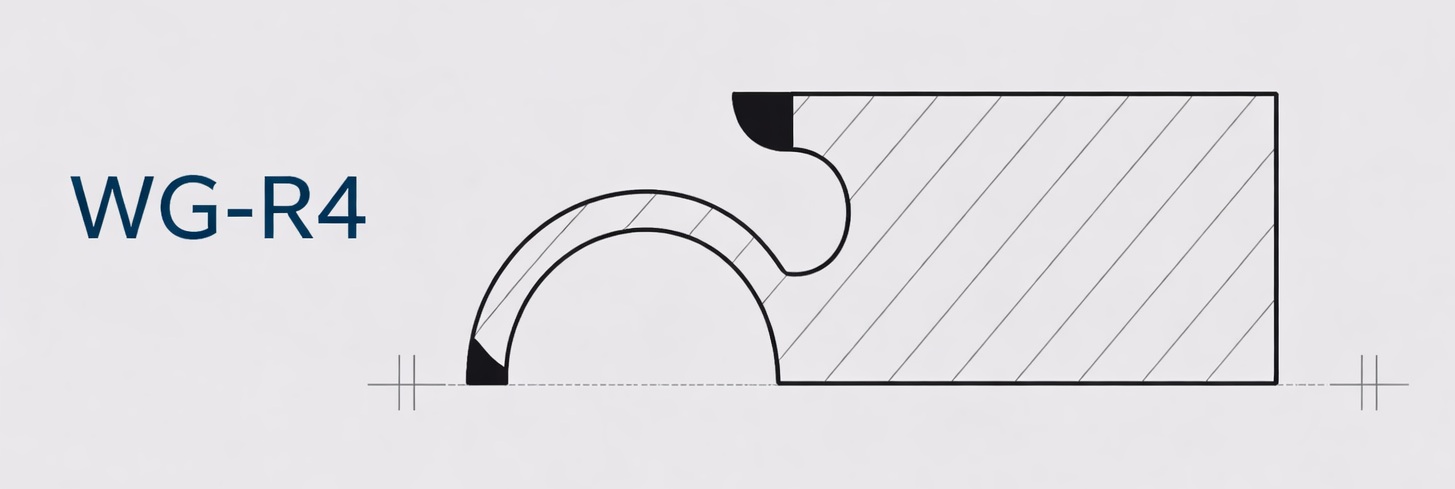

Advanced sealing solution with hollow-lip welded ring, especially recommended for large diameter joints. Offers greater resistance to thermal and pressure shocks compared to WG-M and WG-R1 models. Capable of compensating high axial and radial differential expansions; extremely resistant to thermal and pressure shocks. |

|

Typical thickness: 20 mm - Re-weld times: from 2 to 4 - Radial compensation: 5 mm |

|

(*) In compliance with DIN 2695:2002 for DIN flanges.

All welded rings can be manufactured according to customer drawings.

Applications

These weld ring gaskets represent a permanent metallic sealing solution, used in applications where sealing reliability is essential and the need for joint disassembly is limited. The welds associated with this type of gasket are sealing welds and not structural, since their function is exclusively to ensure the continuity of the sealing barrier, not to contribute to the mechanical strength of the connection.