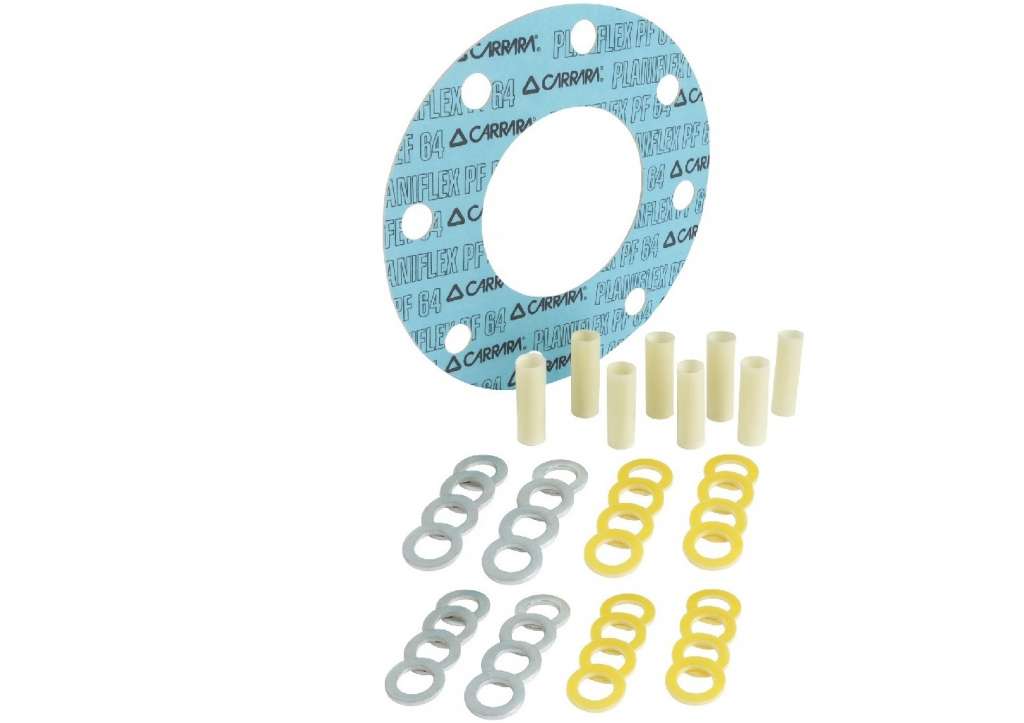

The Guardian Basic ICSF flange isolation kit uses Planiflex® PF64 as its sealing and electrical insulation element, a gasket made of carefully selected aramid fibers and NBR rubber to ensure high performance in a wide range of industrial applications.

Planiflex® PF64 is suitable for continuous use within a temperature range of -40°C to +250°C, with pressure resistance up to 300 lbs and PN40 ratings. Its characteristics make it compatible with the typical pH range of nitrile rubbers, making it suitable for sealing vapors, lubricants, solvents, gases, steam, and various diluted acids and alkalis.

Electrically, the material offers a dielectric strength of about 20 KV/mm, ensuring a satisfactory level of protection in many corrosion isolation applications.

To achieve the best performance from the Guardian Basic ICSF system, the use of insulating sleeves and washers in GRE (Glass Reinforced Epoxy) is always recommended, as they ensure superior stability and durability compared to other materials.

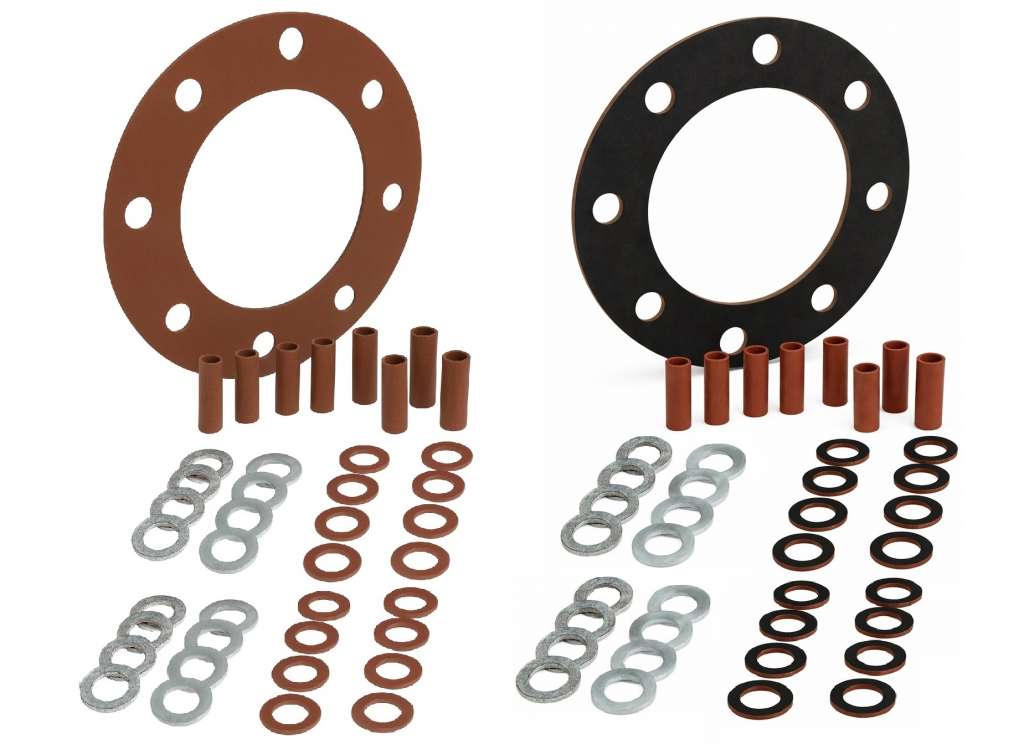

The Guardian Basic IE flange insulation kit uses a phenolic material as its sealing and electrical insulation element, offering solid and reliable performance in standard applications.

In the Guardian Basic IER version, the gasket and the washers can be further coated with rubber, a solution that reduces permeability and improves performance under specific operating conditions.

The washers and sleeves are supplied in phenolic material in the standard configuration; however, for greater efficiency and durability, the use of GRE G10 (FR4) is recommended, a composite made of glass-fiber-reinforced epoxy resin. Thanks to its lower permeability compared to phenolic materials, GRE G10 ensures better long-term stability of the sealing and insulation system, reducing the risk of performance loss due to degradation of auxiliary components.