A weld ring gasket, also commonly referred to as a lip seal weld ring, consists of a pair of metallic rings. Each individual ring is first welded to its respective flange face. Upon assembly of the joint, the two rings are then welded together at their outer periphery to complete the seal.

The use of weld ring gaskets is recommended when conventional gasket types are considered unsuitable and when joint disassembly is infrequent. These gaskets are generally classified as semi-detachable, since the welded connection between the sealing rings must be cut in addition to removing the flange bolts to open the joint.

Several designs of weld ring gaskets are available, including:

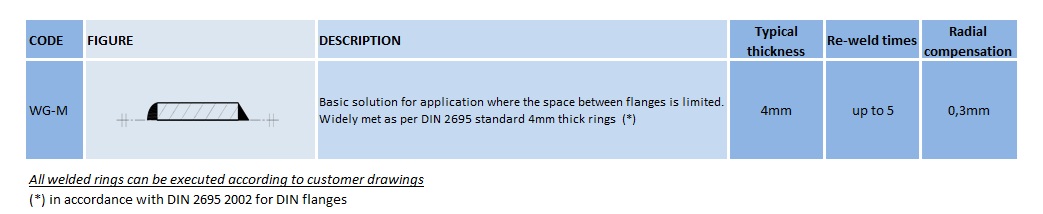

Membrane weld ring gaskets

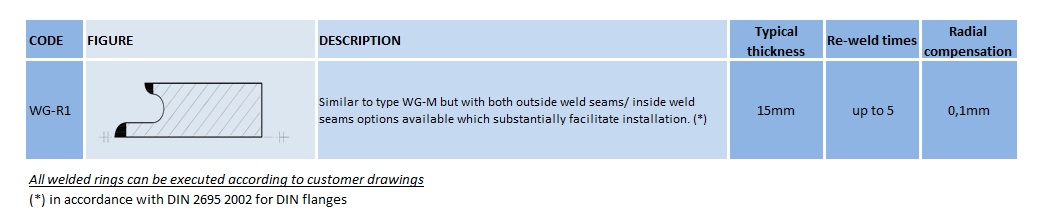

Profiled weld ring gaskets

Hollow-lip weld ring gaskets

Membrane weld ring gaskets and weld ring gaskets are not suitable for accommodating significant radial differential expansion between the connected components. Depending on the specific design of the gasket, the allowable radial movement can be as low as 0.1 mm (0.004 inches) and should not exceed 0.5 mm (0.02 inches).

A membrane weld ring gasket typically consists of two matching metal rings, each with a thickness of approximately 4 mm (0.16 inches). These rings are made from materials that are either identical or compatible with the flange materials, in order to ensure:

chemical and weld compatibility,

thermal conductivity alignment,

and minimization of radial differential stresses.

Each ring is individually welded to its corresponding flange using an internal joint weld. After both rings are secured, a second welding step is performed along the outer diameter, creating a fully welded, sealed joint.

The welds used in this configuration are classified as seal welds, meaning they are intended to ensure leak-tightness, rather than to provide structural strength.

The width of the weld ring gasket must be engineered to withstand internal pressure, particularly acting in the circumferential (hoop) direction, ensuring mechanical stability and integrity under operating conditions.

Weld ring gaskets, also known as lip seals or weld ring seals, represent a permanent metallic sealing solution used in applications where sealing reliability is essential and joint disassembly is limited.

The welds associated with this type of gasket are seal welds, not structural welds, as their purpose is solely to ensure the continuity of the sealing barrier rather than to contribute to the mechanical strength of the connection.

The width of the ring must be designed to withstand the internal pressure acting in the circumferential (hoop) direction.

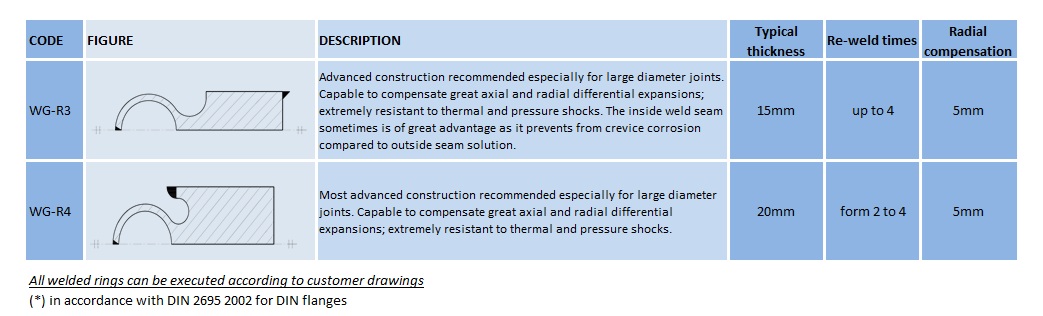

The most common configurations — solid-body and hollow-lip types — generally feature a sealing body thickness of about 15 mm.

Hollow-lip gaskets provide more favorable stress conditions in the sealing weld area and a greater ability to absorb joint movements or deformations, making them particularly suitable where radial thermal expansion differences between flanges may occur.

Depending on their geometry, these gaskets can compensate for radial expansion differences of up to approximately 5 mm.

Under critical operating conditions, it is recommended to perform a Finite Element Analysis (FEA) or Finite Difference Analysis (FDA) on the flanges associated with the joint to determine the relative radial movement and its effect on weld stress in the gasket area.

Such verification is especially necessary when the flange and gasket materials have significantly different coefficients of thermal expansion, when flanges have non-uniform thermal masses with operating temperatures above 93 °C, or when the service temperature exceeds 176 °C.

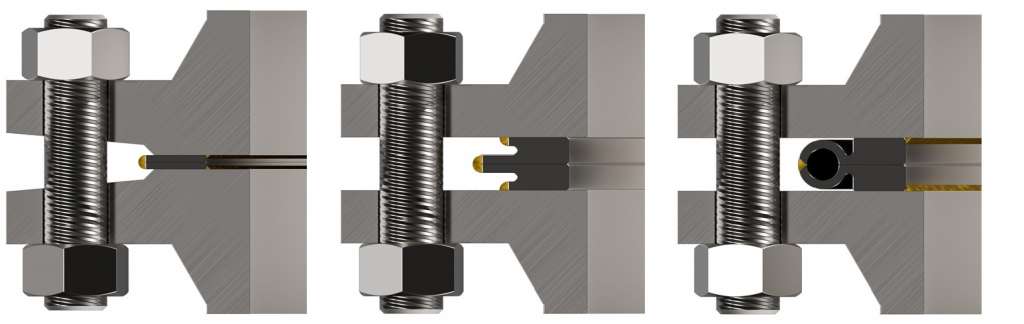

It is also important to ensure that there is sufficient space for executing the seal weld along the outer edge of the gasket.

If the available space does not allow it, special flanges with a bevel between the mating surfaces can be adopted, in order to provide access to the weld area without compromising the strength of the joint.

When weld ring gaskets are used as a replacement for conventional gaskets in existing joints, it must be considered that they are self-energizing seals and therefore do not require compression loads to maintain sealing.

The tightening of the flange bolts serves only to counteract hydrostatic thrust and external axial or bending loads.

It is therefore necessary to verify the suitability of the existing flanges and bolting in accordance with the applicable design code.

From a geometrical standpoint, the sealing body is normally aligned with, or slightly protruding beyond, the outer edge of the flange mating surface, while the welding lips extend beyond the main body.

It is therefore essential to ensure sufficient clearance between the gasket and the flange bolts; if this is not possible, the gasket body may be positioned within the outer diameter of the mating surface — a solution not applicable to membrane-type versions.

Finally, a slight bevel on the flanges may be required to provide adequate working space for welding the lips.

The joint configuration must be verified considering both the position of the gasket and any beveling, to ensure that the strength and integrity of the flanges remain compliant with the design requirements.