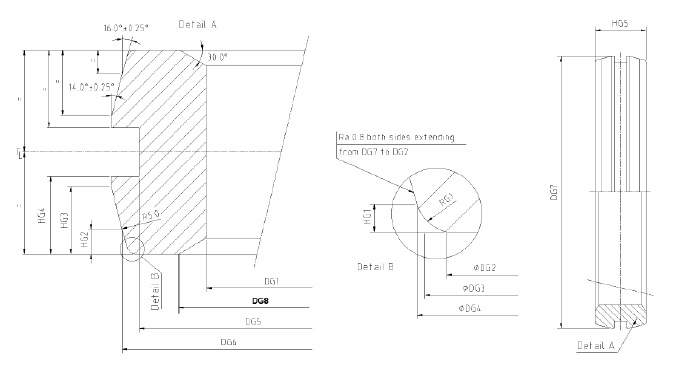

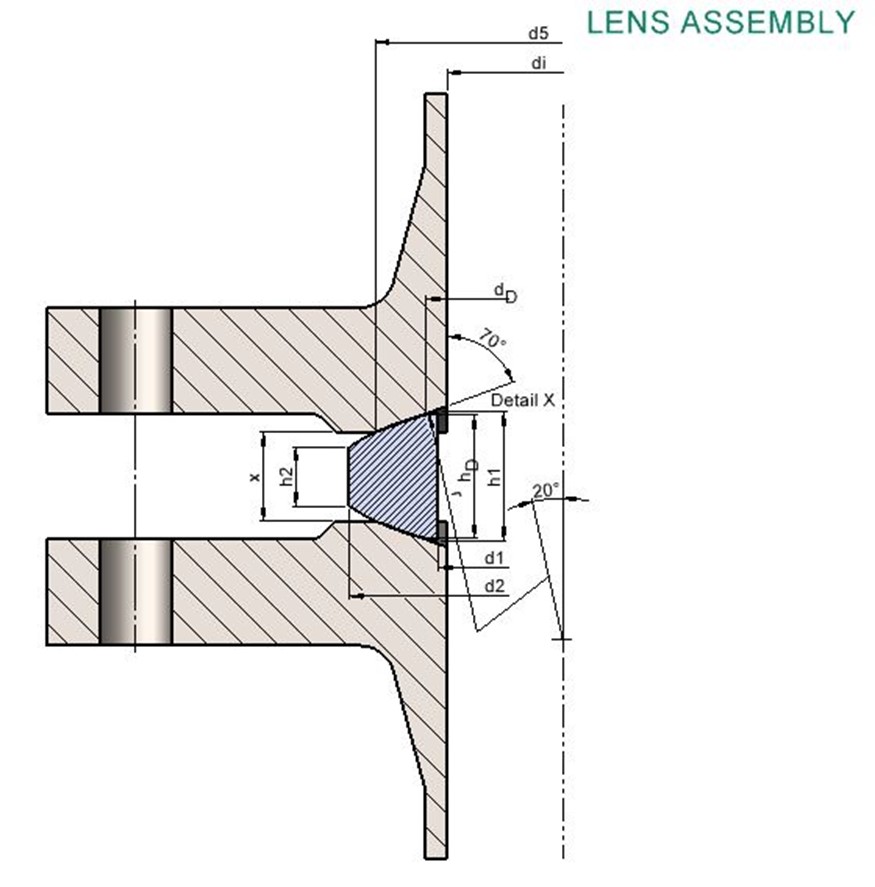

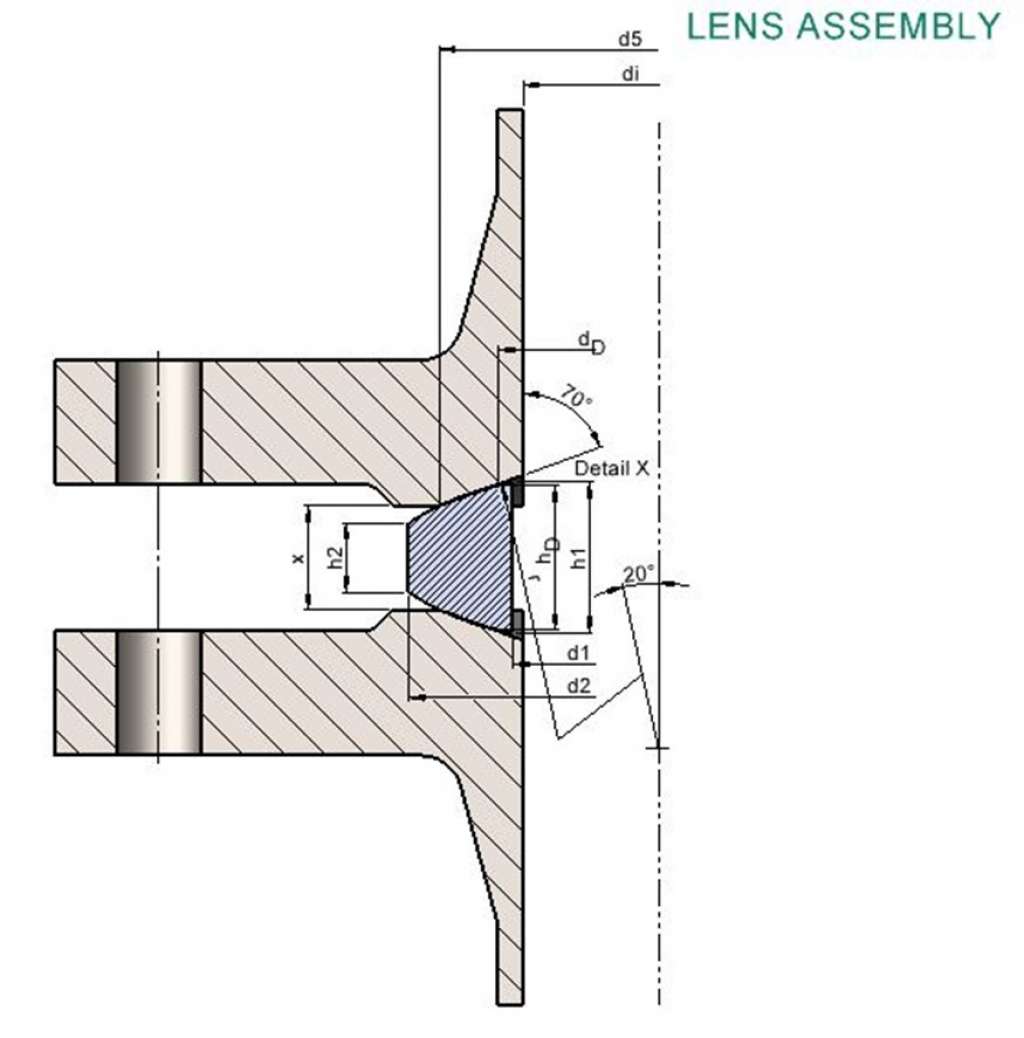

When the flanged connection is assembled, bolt tightening presses the flange against the conical sealing surfaces located on the outer diameter of the IX Seal Ring. This type of joint is typical of compact flange systems, designed to operate under extreme pressure and temperature conditions, ensuring high sealing performance in reduced spaces.

The compact flange assembly incorporates two sealing barriers: a primary one, provided by the IX Seal Ring itself, and a secondary one, resulting from the mechanical stress applied to the flange heel during tightening. As with API Ring Type Joint gaskets, IX Seal Rings are manufactured with extremely tight tolerances and under strict quality controls to ensure precise matching with the sealing surfaces.

The choice of materials plays a crucial role in ensuring mechanical strength and chemical compatibility, especially in environments subject to chloride, H₂S, or CO₂ corrosion. To facilitate identification and prevent errors during installation, IX gaskets are marked with a color code indicating the metal type, in accordance with NORSOK L-005 standards.

IX Seal Rings represent a highly reliable solution for offshore plants, pipelines, and critical applications in the oil & gas industry.