The current industrial landscape shows a growing demand for flange insulation kits compliant with ASME B16.5, ASME B16.47 Series A and B, API 6A, and EN 1092-1 standards, designed to protect piping systems from galvanic corrosion.

Oil and gas facilities, refineries, LNG terminals, offshore platforms, chemical and petrochemical plants, as well as major energy infrastructures, increasingly rely on insulating kits to ensure the integrity and safety of their piping systems, as they:

-

Prevent stray electrical currents from propagating, thus avoiding galvanic cell formation and the resulting corrosion phenomena.

-

Provide reliable electrical isolation and sealing performance, supporting cathodic protection systems while ensuring the longevity and safety of pipelines.

-

Withstand high pressures and temperatures up to 150°C, aggressive fluids, and variable installation conditions in full compliance with international industry standards.

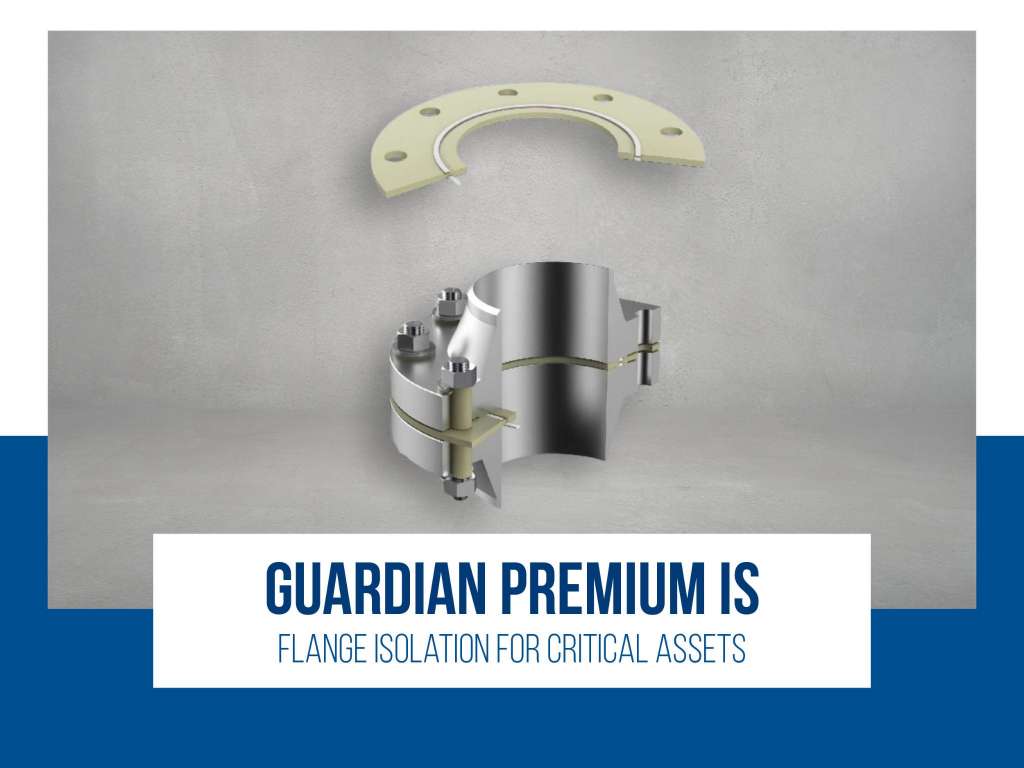

Among the available solutions, the Guardian Premium IS offers exceptional versatility, fully compliant with NACE SP0286 guidelines and suitable for the entire ANSI 150–1500# and API 2–5K# pressure range at a maximum temperature of 150°C.

The Guardian Premium IS kit stands out for its:

-

Absence of metallic components: the GRE (Glass Reinforced Epoxy) acts both as insulating element and retainer, eliminating the weaknesses typical of metallic solutions.

-

Installation flexibility: the Guardian Premium IS gasket is suitable for RF, FF, and RTJ flanges, replacing traditional phenolic ring joints often responsible for suboptimal sealing.

-

Reliable sealing performance: available with high-performance elastomers and polymers (PTFE, NBR, FKM, etc.), it ensures maximum tightness even under high mechanical loads, thanks to an innovative groove design that houses the sealing element, preventing retainer breakage and enhancing flexibility and overall sealing efficiency.