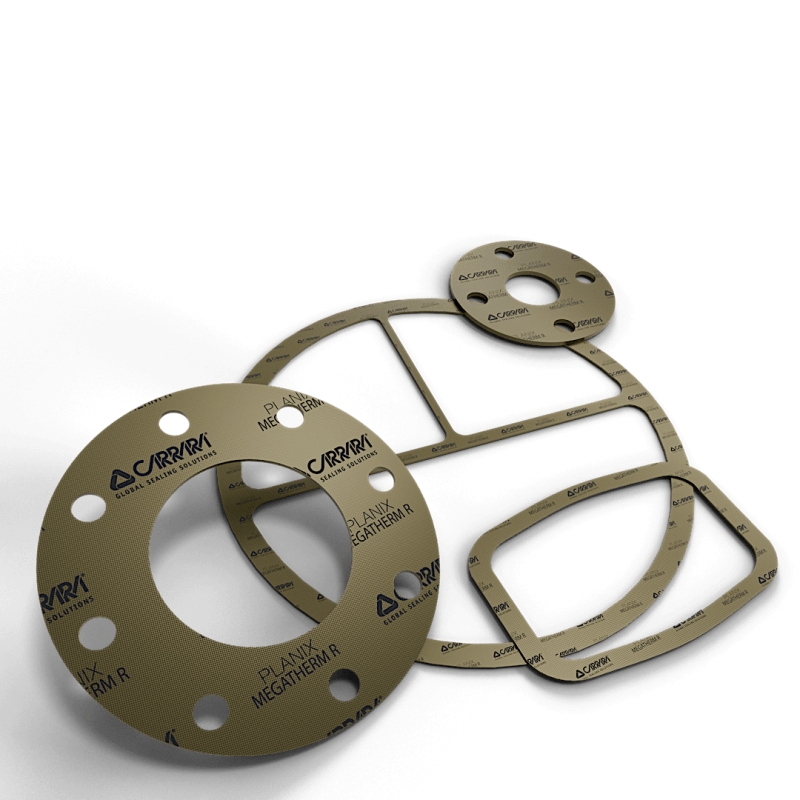

Composition

MEGATHERM R is a gasket sheet that combines the robustness of flogopite mica, the versatility of silicone resin, and the perforated SS316L metal support. The balanced composition of these materials gives the product excellent thermal, chemical, and mechanical resistance.

Characteristics

The presence of flogopite mica, silicone resin, and the perforated SS316L metal support make MEGATHERM R an outstanding option for applications requiring superior performance. This gasket sheet offers exceptional thermal resistance, advanced chemical resistance, and superior durability compared to traditional gaskets made of ceramic fiber or similar materials. MEGATHERM R stands out for its ability to maintain performance even in extreme environmental conditions. The perforated SS316L metal support provides a solid structure, while flogopite mica and silicone resin provide flexibility and resistance to external agents.

Applications

Designed for the production of flange gaskets, MEGATHERM R is ideal for situations where the use of graphite gaskets is not possible due to high temperatures or the presence of oxidizing fluids. This sheet offers reliable and long-lasting performance in a wide range of industrial applications, overcoming the limitations of traditional gaskets and ensuring efficient and durable sealing.