Composition

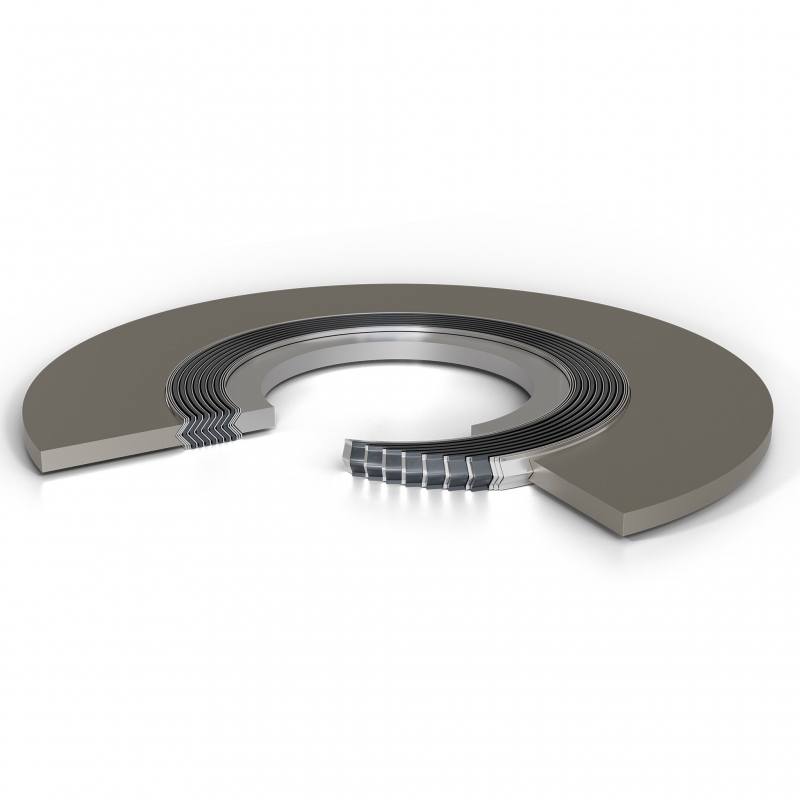

Spiral wound gaskets are manufactured by coiling a V-profile metal strip together with a soft filler material, forming a flexible and pressure-resistant sealing element. The metal strip provides structural integrity and elasticity, while the filler ensures effective sealing performance. To enhance stability, control compression, and facilitate installation, the winding is supported by an outer guide ring and typically by an inner ring for RF flanges. Spiral wound gaskets for LMF flanges should be supported by an inner ring, although this is not mandatory, while those for LTG flanges are supplied without rings. The metal used for the inner rings matches that of the metal strip, whereas the guide ring material is user-selected. The stamped markings and color codes on the spiral wound gasket comply with ASME B16.20.

- Metal strip: any type of steel or alloy is available

- Filler: industrial graphite 99% Carbon content

Characteristics

Planisteel SW G OXY spiral wound gaskets are primarily manufactured in accordance with ASME B16.20, ASME B16.47 Series A and B, EN 12560-2, and EN 1514-2 standards, but gaskets made to other international standards or customized specifications are also available.

Planisteel SW G OXY spiral wound gaskets are BAM Approved, specifically designed and manufactured for high-concentration oxygen service applications. Made with selected materials and certified processes, they ensure maximum safety and absence of contaminants, providing high reliability in highly reactive environments.

BAM Approvals no. 15019238E and 15019236E.

| Performance Specifications | UM | Value |

|---|---|---|

| Minimum temperature | °C | -200 |

| Maximum temperature - Oxygen Concentration 100% | °C | 300 |

| Maximum Temperature - Blended Oxygen | °C | 450 |

| Maximum Pressure - Oxygen Concentration 100% | bar | 250 |

| Maximum Pressure - Blended Oxygen | bar | according to the gasket rating |

| Min. Gasket Seating Stress - Sgmin-SL=0.001 | MPa | 42 |

| Min. Gasket Operating Stress - Sgmin-O | MPa | 30 |

| Max Gasket Operating Stress - Sgmax | MPa | 280 |

The sealing factors were obtained from tests carried out on the SWCI design.

This data sheet is for Oxygen Services. Graphite is not allowed with oxdiizing fluids. With non-oxidizing fluids, the maximum temperature of 550°C refers to the RF flange applications while for those LMF and LTG the limit is 650°C.

Applications

Spiral wound gasket for industrial applications with liquid and gaseous oxygen.