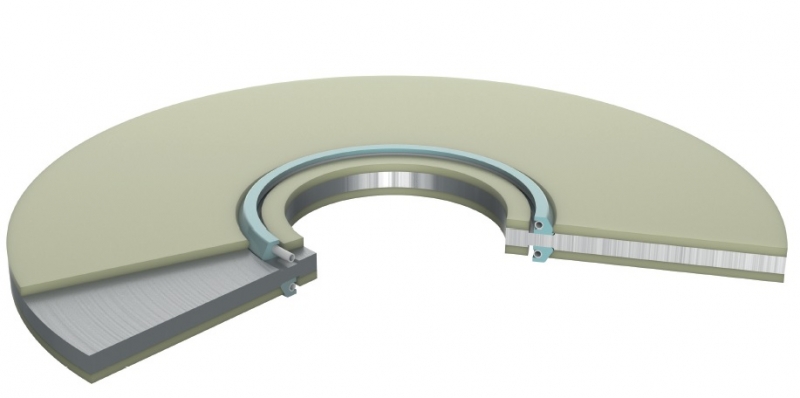

Composition

- Gasket + sealing layers

- Thickness: 6.35 mm (0.250”)

- SS316 Metal Core (other available on demand)

- Thickness: 3.00 mm (0.120”)

- GRE Laminate (for side)

- Thickness: 1.60 mm (0.065”)

- Option A: G10 (FR4)

- Option B: G11 (FR5)

- Thickness: 1.60 mm (0.065”)

- Sealing Element

- Option A: PTFE with SS spring

- Option B: NBR

- Option C: FKM

- Insulating sleeves

- Thickness: 0.90÷1.10 mm

- Option A: GRE G10 (FR4)

- Option B: GRE G11 (FR5)

- Thickness: 0.90÷1.10 mm

- Insulating washers

- Thickness: 3.00 mm

- Option A: GRE G10 (FR4)

- Option B: GRE G11 (FR5)

- Thickness: 3.00 mm

- Metallic Washers

- Thickness: 3.00 mm

- Option A: Zinc Plated Carbon Steel

- Option B: Other metals on request

- Thickness: 3.00 mm

Applications

Insulating kit for flanges.